Learn more about the high-performance piston assembly dedicated to the Suzuki M13A model, and discuss its excellent power performance and long-term durability. This article will analyze the manufacturing process, material selection and installation and maintenance points of the product in detail to help car owners better understand and choose the core components suitable for their vehicles. Whether it is daily driving or extreme challenges, this piston assembly can provide you with stable power output and smooth operation experience.

Explore the core of Suzuki M13A engine: the importance of piston assembly

When we talk about the Suzuki M13A model, we cannot ignore its powerful and reliable engine system. One of the most critical part is the piston assembly, which drives the entire engine like a heart. The correct selection of the appropriate piston assembly can not only significantly improve the performance of the vehicle, but also greatly extend the service life. For modern car owners, in the face of a dazzling array of alternatives on the market, it is particularly important to understand what is the real high quality accessories. Fortunately, Suzuki has tailored a set of efficient solutions for this classic model that has been selling for many years-the focus of our discussion today.

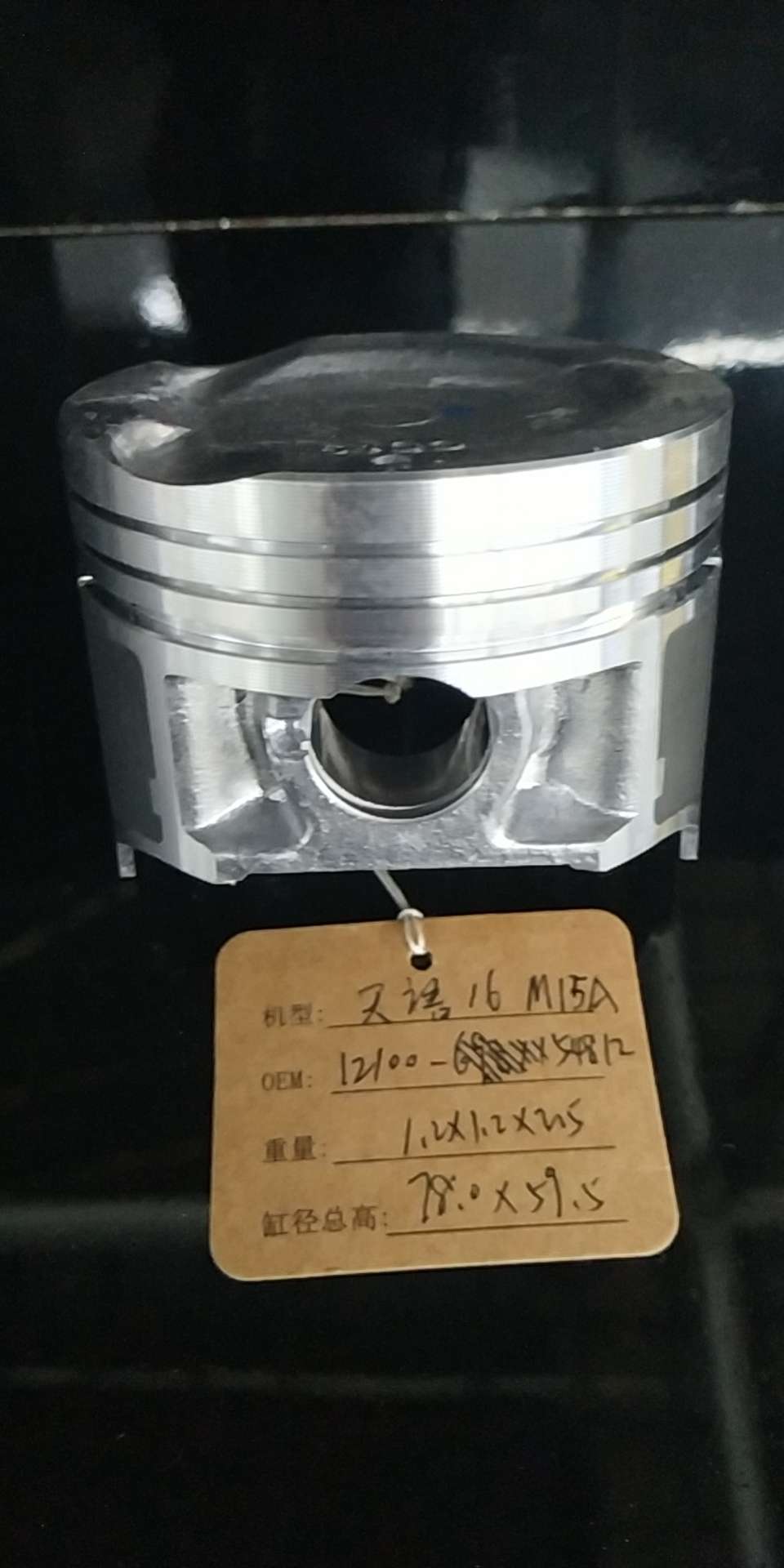

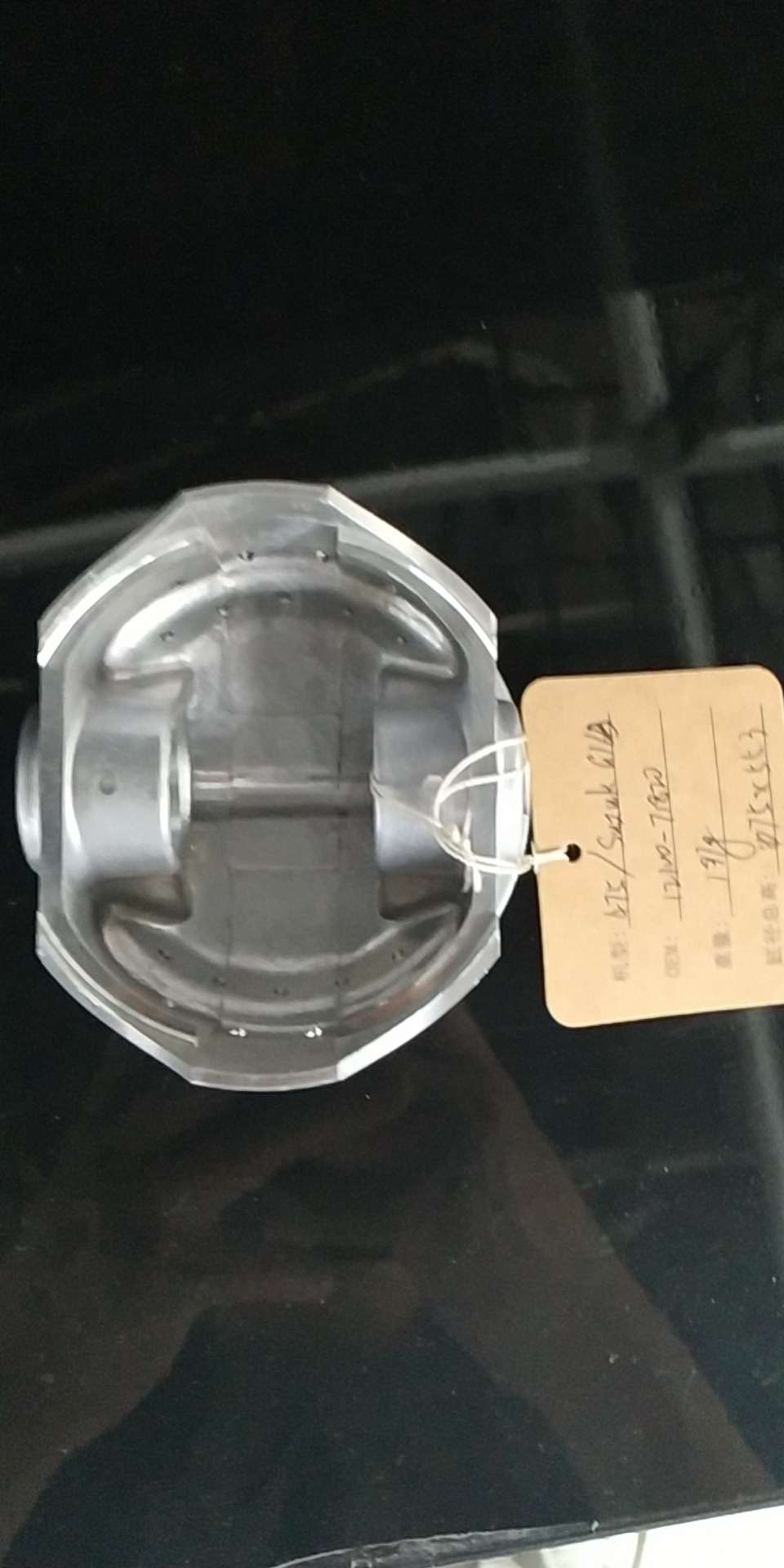

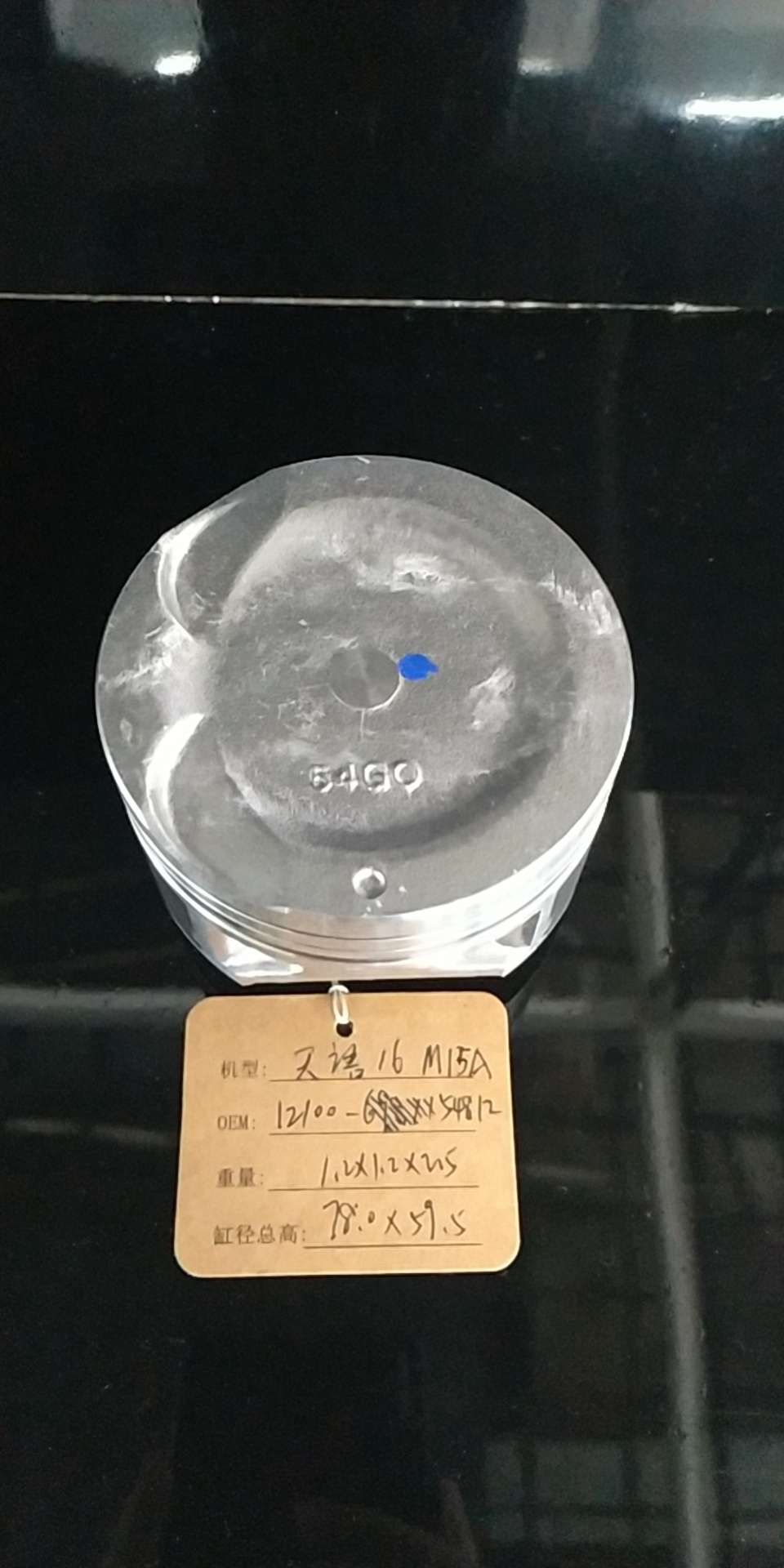

Precision Crafting: Demystifying the high quality Manufacturing Process

In order to ensure that each part can withstand the test of time, extremely strict standards are used in the production process. From the raw material procurement stage began to strictly select suppliers, and through multiple testing procedures to confirm the quality of qualified before putting into use. Next is the crucial forming process, with the help of advanced CNC machine tools to accurately cut and polish the blank parts; then enter the special processing link, such as heat treatment can increase the hardness to prevent deformation, and the surface coating can enhance the wear resistance and corrosion resistance. Finally, it has to go through a series of strict quality control processes before it can be packaged and shipped to old customers waiting for replacement around the world. All these efforts are to make every user who trusts and supports us enjoy the best service and protection.

Material is everything: Selected materials guarantee excellent performance

The main components of this piston assembly include high-strength aluminum alloy and other special alloy steel and other high-quality metal materials. The former is widely used in the engine field due to its light weight and good thermal conductivity, while the latter performs well in extreme working environments due to its excellent mechanical properties. In addition, some auxiliary substances have also been cleverly integrated into the design, such as graphite lubricants to help reduce frictional resistance and reduce energy loss; sealing gaskets effectively prevent oil leakage to protect the internal structure from damage. All these carefully selected ingredients work together to create a powerful engine of strength and flexibility, the central nervous system.

Installation guide and maintenance tips: make your investment more worthwhile

If you are exposed to such a complex mechanical component for the first time, you may find it a bit tricky, don't worry! The official team has already prepared a detailed and easy-to-understand collection of teaching materials for everyone, covering everything from the list of required tools to specific operation steps to solutions to possible problems. Following the instructions to implement step by step can not only make the whole process much easier and faster, but more importantly, reduce the risk factor of misoperation. In addition, it is worth mentioning that regular inspection and cleaning cannot be ignored. Timely removal of carbon deposits and dirt can effectively delay the aging speed, thus improving efficiency and reducing fuel consumption costs. In a word, as long as the relevant recommendations are carefully implemented in accordance with the norms, the best benefits can be maximized.

Actual test data speak: real-world performance verification

In order to prove that this piston assembly is indeed worthy of its name, the R & D personnel have conducted a large number of rigorous and detailed research experiments. These include, but are not limited to, accelerated life test (ALT) to simulate fatigue damage under long-term continuous operation. The results show that it has obvious advantages compared with similar competitive brand products on the market, especially in terms of compressive and seismic resistance. Not only so many authoritative third-party evaluation agencies have also given high recognition and praise, further confirming this point. Now you can fully trust such an excellent program that has been verified by many parties to protect your car's safe and smooth driving every day.

Voice of Users: Listen to Real Feedback from Car Owners

In addition to the professional evaluation report, it can best reflect whether a good thing is really popular than the personal experience sharing of consumers. In this report, we also specially collected some comments from car owners who have changed the same configuration. Some ordinary family car drivers mentioned that they felt that the car was running faster and more stable than before after changing the new piston. Some racing enthusiasts also pointed out that there was no abnormal shaking even when turning at high speed and braking sharply. By listening to their stories, we can see that they have excellent performance records in daily travel and fierce competition occasions, which undoubtedly injects strong confidence support into more hesitant friends.

Future Outlook: Technology Innovation Leads Industry Development Trend

Looking at today's automotive industry is facing an unprecedented period of change, especially when the wave of new energy revolution is sweeping the world, the traditional fuel auto parts market has also undergone profound adjustments and changes. However, even in this context, there are still many companies committed to continuous innovation and breakthroughs to seek a better development direction. It is expected that in the next few years, as the research and development of new composite materials gradually matures, the scope of application will continue to expand; intelligent automated production lines will also be widely used to significantly reduce costs and increase production capacity. At that time, we will usher in a batch of more competitive new-generation high-performance piston assemblies, and continue to provide users with value returns and service enjoyment beyond expectations.