Uncovering the mystery: understanding the Suzuki M13A piston assembly

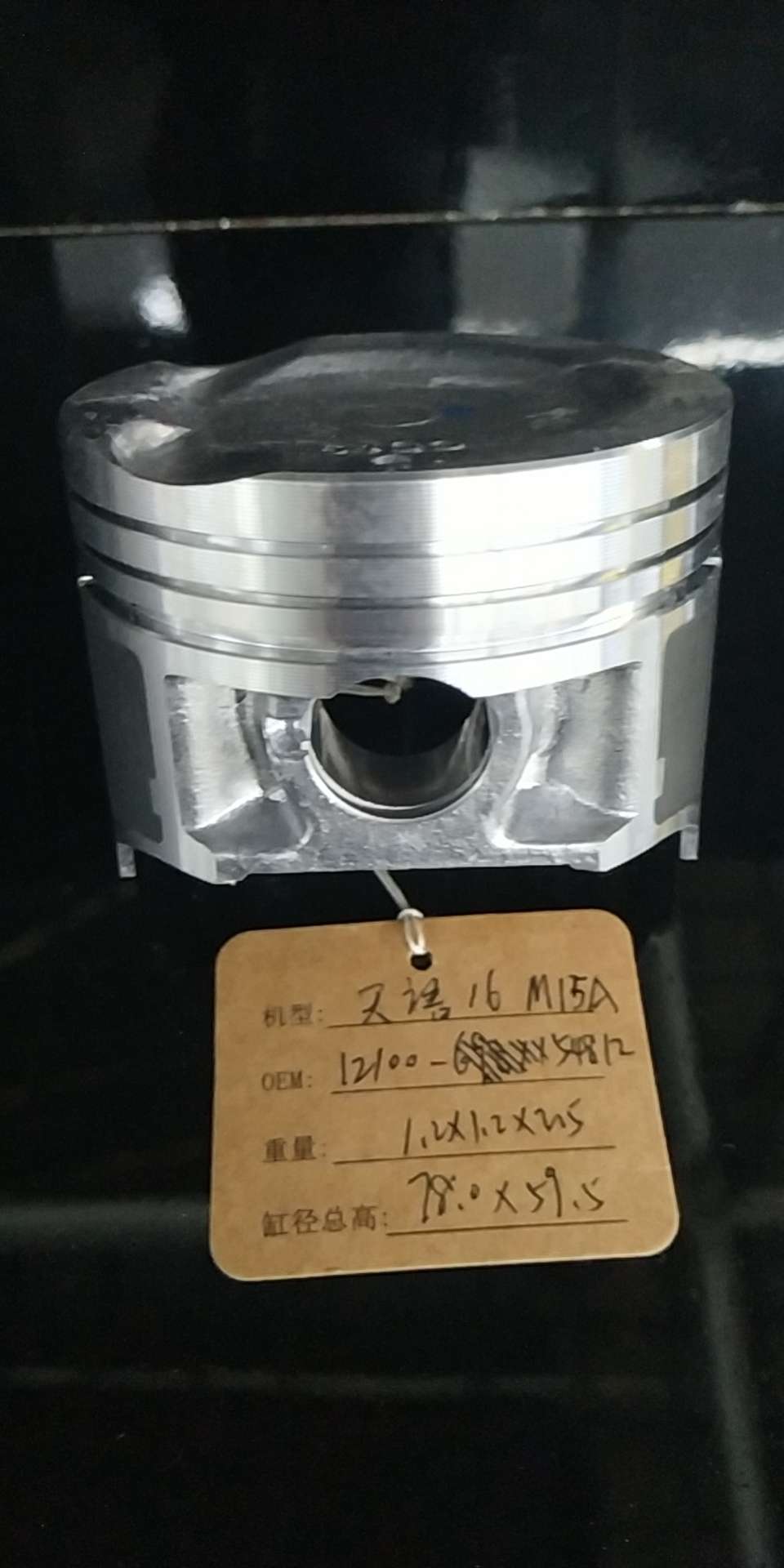

As a classic model loved by consumers, the piston assembly, the heart of the Suzuki M13A, is undoubtedly the most noteworthy part. It is composed of piston, connecting rod, crankshaft and other precision parts, each link is very important. When the engine is running, the piston reciprocates up and down inside the cylinder, and drives the crankshaft to rotate through the connecting rod, thereby generating a strong driving force. It can be said that the piston assembly is not only the power source to promote the car forward, but also one of the key indicators to measure the overall performance of a car.

The source of performance: the working principle of the piston assembly

In order to give everyone a more intuitive understanding of how the piston assembly works, we can imagine it as a small "energy conversion station". Here, the combustible gas formed by the mixture of fuel and air explodes violently when the spark plug is ignited, producing high temperature and high pressure gas. This part of the gas expands rapidly, pushing the piston down, and then driving the connecting rod and crankshaft to complete the rotation. As this cycle continues to repeat, the car is able to gain continuous forward momentum.

Material Selection: high quality Materials Achieve High Performance

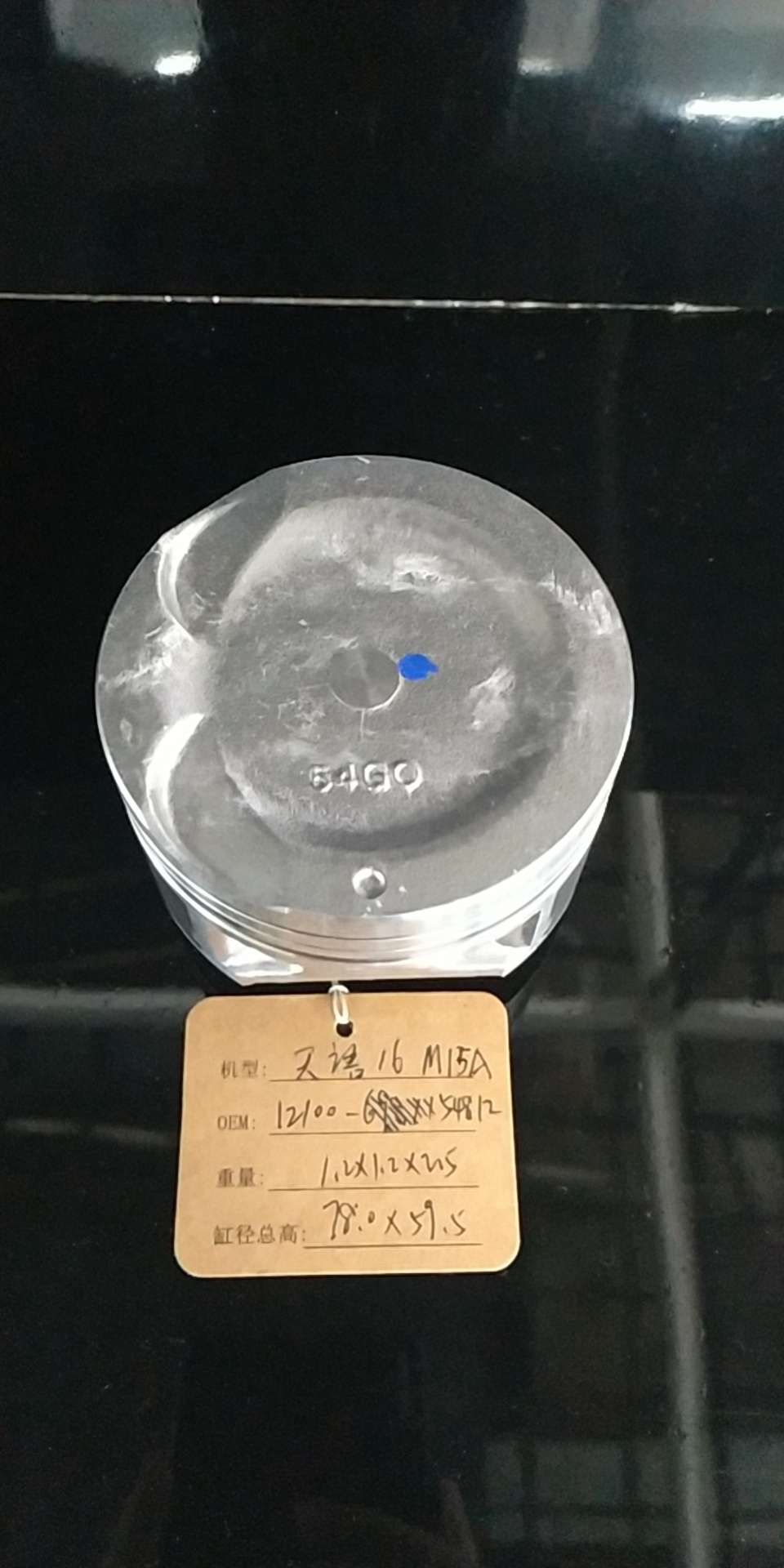

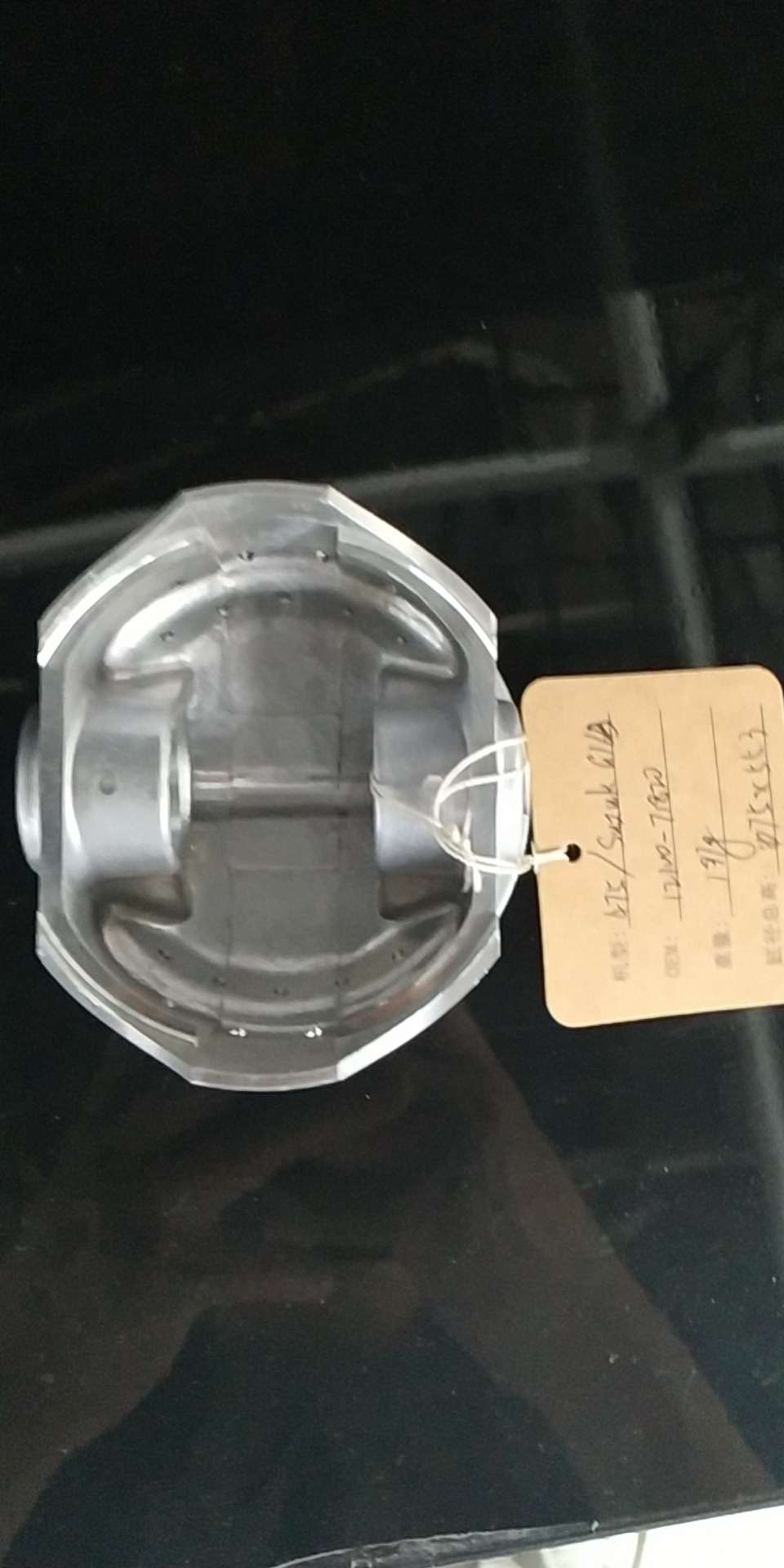

In the pursuit of extreme performance, the choice of materials is particularly important. The Suzuki M13A piston assembly uses advanced materials such as high-strength aluminum alloy and cast iron. The former is light in weight and high in strength, which helps reduce the burden on the engine and improve the acceleration response speed; the latter has excellent wear resistance and thermal stability, even for a long time It can maintain good working conditions in a high temperature environment. It is the application of these high-quality materials that allows the piston assembly to perform well under extreme conditions.

Details Determine Success or Failure: Assembly Skills and Precautions

No matter how sophisticated the product is, if it is not installed correctly, it will not be as effective as it should be. Therefore, extreme care must be taken when assembling the piston assembly. First of all, you need to prepare special tools, and then strictly follow the manual provided by the manufacturer to operate step by step. From removing the old parts to installing the new parts, you must carefully check every step. In particular, it should be noted that the tightening force of the screws at all connections should be moderate, and too tight or too loose may cause damage. Optimum performance of the piston assembly can only be ensured by following the standard procedure.

Care: Routine Maintenance and Troubleshooting

Good maintenance habits can not only extend the service life of the piston assembly, but also effectively prevent the occurrence of failures. It is recommended that car owners conduct a comprehensive inspection of the engine at regular intervals, especially paying attention to whether the piston ring is worn and whether the lubricating oil is sufficient and clean. Once problems are found, timely measures should be taken to solve them, and no delay should lead to greater losses. In addition, the rational use of high-quality oil and filters is equally important, which not only reduces wear and tear, but also helps improve overall work efficiency.

Performance upgrade: the possibility of modifying the piston assembly

For some owners who pursue extreme performance, the original configuration may be difficult to meet their needs. Fortunately, there are many high-performance piston assemblies specially customized for Suzuki M13A on the market. These retrofit parts are usually made of more advanced technology and materials, which can significantly increase power output without sacrificing reliability. However, before making a purchase decision, be sure to fully consider your actual situation and weigh the pros and cons before making a choice.

Case Study: Successful Maintenance Experience Sharing

Next, let us use two real cases to see how to effectively deal with piston assembly-related failures. The first example is an old M13A with a mileage of more than 100000 kilometers. Due to a long period of lack of maintenance, the piston ring was severely worn and there was an obvious power drop. After professional testing and evaluation, the technician decided to replace the entire piston assembly. After this overhaul, the vehicle returned to its former style and was once again rejuvenated. The second case is a story about a chain reaction caused by a leak in the cooling system. At first, it was only a small problem, but due to the failure to be dealt with in a timely and effective manner, it eventually evolved into a major accident. This shows how necessary regular inspection and maintenance is.