When it comes to Suzuki M13A series engines, many people first think of its reliability and stability. However, behind these outstanding performances, there is a vital component that cannot be missed-the Suzuki M13A piston assembly. Today we will uncover the unique charm of this high quality part.

Decoding Suzuki M13A: the key component behind high performance

As one of the representative works of a classic small-displacement four-cylinder engine, M13A not only has a strong power output but also takes into account excellent fuel economy. All this is inseparable from its core part-the role of the piston assembly. The device is responsible for converting the pressure generated in the combustion chamber into the actual power source that propels the crankshaft to rotate. It can be said that without the support of a good piston system, no matter how good the design concept is, it cannot be fully displayed.

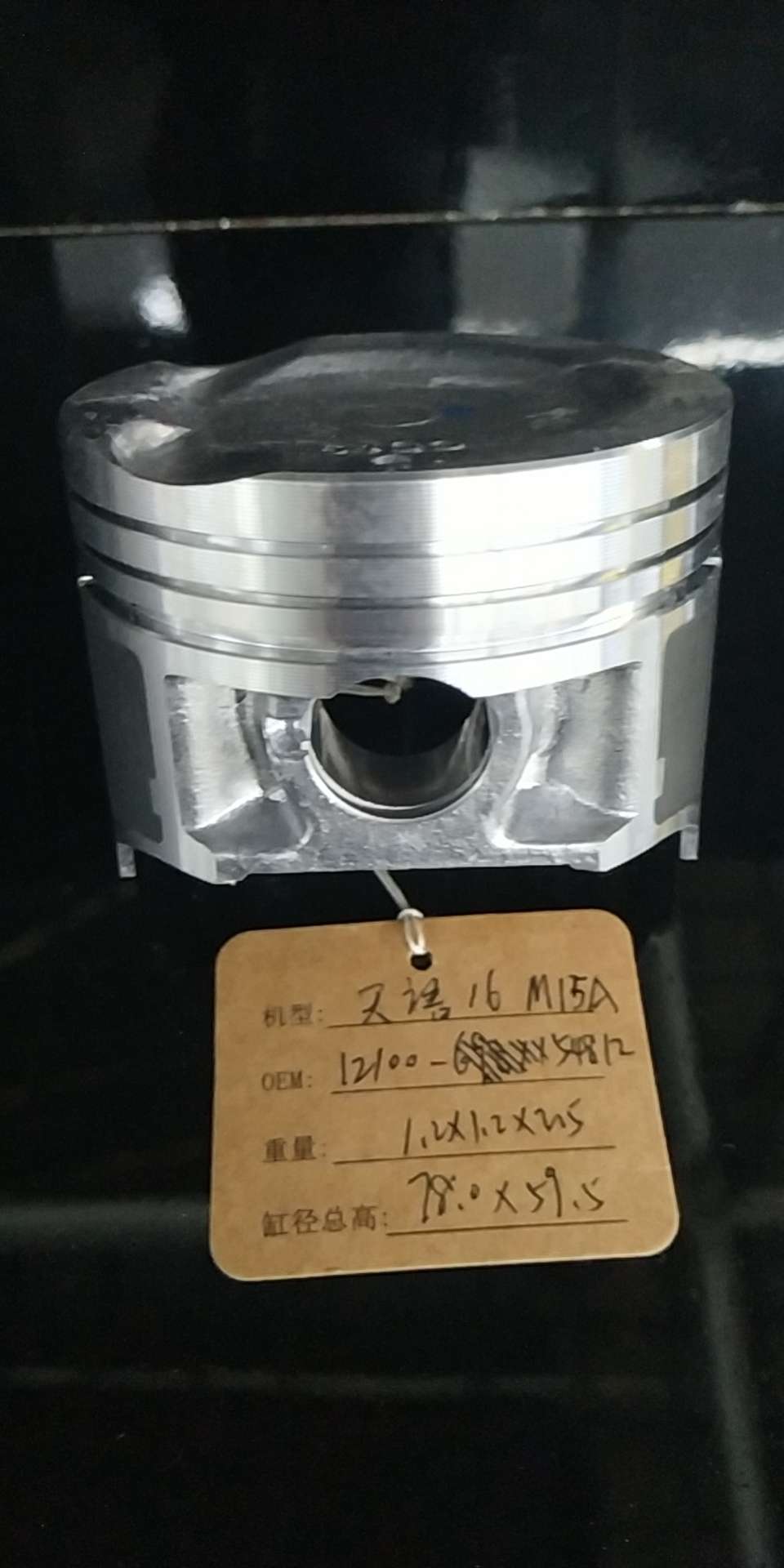

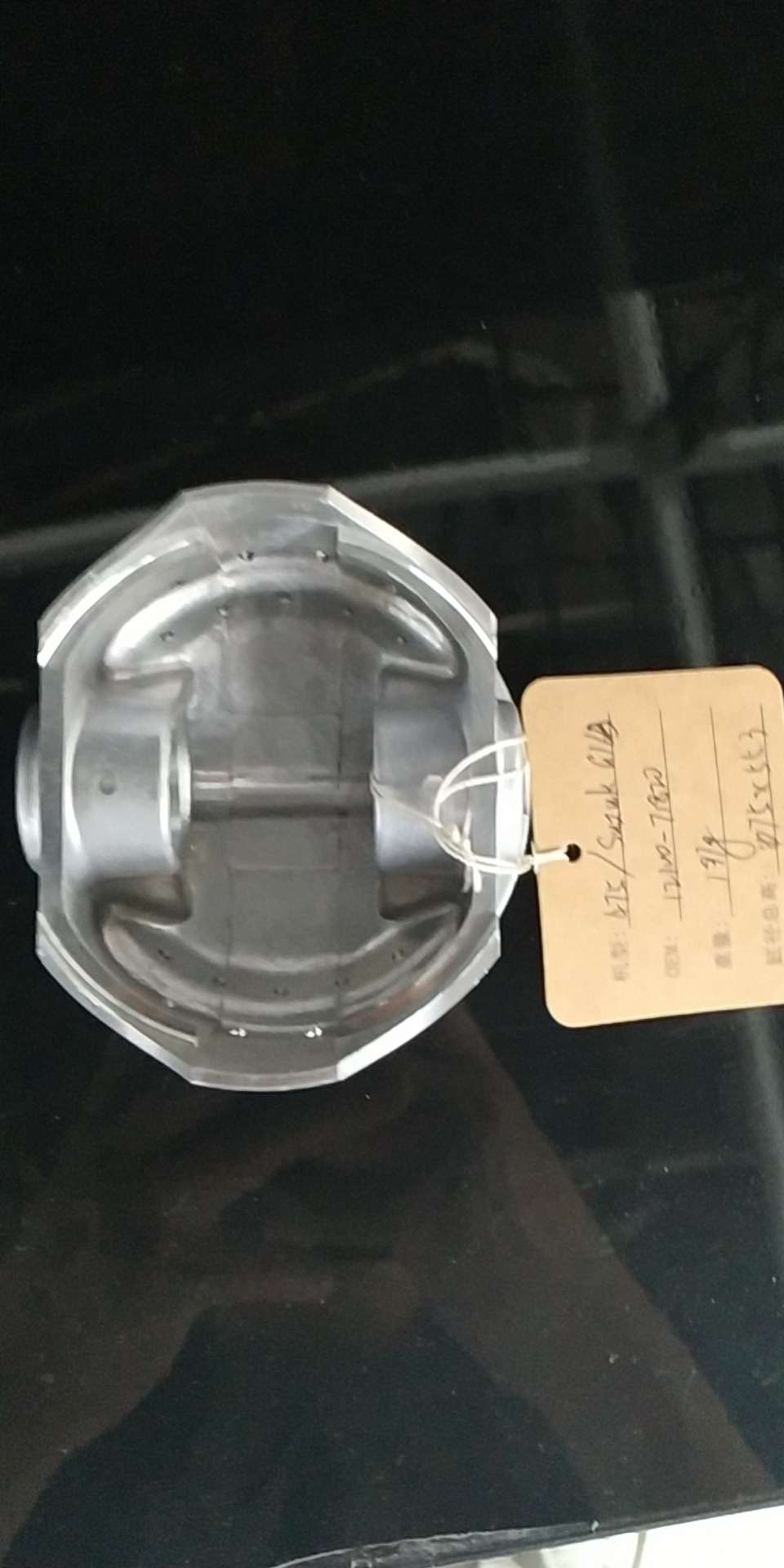

High-quality materials for excellent durability: revealing the essence of the construction of the piston assembly

In order to ensure long-term reliability and durability, Suzuki engineers have carefully selected a series of top materials to manufacture this precision instrument. The most critical part of which is the main piston body made of high-strength aluminum alloy casting and the working surface coating with a smooth surface such as a mirror after special hardening treatment. This combination can not only reduce weight but also increase the anti-wear ability, so that the whole set of equipment can still maintain a stable operation state under high temperature and high pressure environment.

Improving fuel economy and power output: analysis of the technical advantages of the piston assembly

In addition to being sturdy, another important advantage of this piston system is that it can significantly improve the overall performance parameters of the car. By optimizing the internal geometry design, unnecessary friction losses are reduced, and the precise control of the size of each injection with the appropriate ignition timing to achieve a more efficient energy conversion process. In this way, it can not only save valuable energy consumption, but also enhance the acceleration response speed and smoothness, which brings unprecedented control experience to the driver.

Daily maintenance tips: how to extend the life of M13A piston assembly

Although the quality provided by the original factory is excellent, correct and reasonable maintenance is also essential. Regular inspection of the oil level and timely replacement of fresh lubricating oil can effectively prevent the occurrence of dry friction between metals; in addition, paying attention to cleaning up the carbon deposits in the intake pipe can also indirectly reduce the risk of damage to the sealing of the piston ring. As long as you follow the manual guidelines carefully implement the above recommendations can make your car always maintain the best operating conditions for many years.

Practical Case Sharing: Surprise Effect Brought by Successful Modification Experience

Many car owners have experienced the huge changes after the upgrade. A senior enthusiast installed it on his car and found that the fuel consumption per 100 kilometers had dropped by a percentage unit and the sprint performance from zero to 100 kilometers per hour had also been shortened by several seconds! This fully proves the importance of choosing the right type of accessories.

in short, friends who are pursuing extreme speed or simply want to reduce operating costs can consider starting with such a set of high-quality products to add more fun and value returns to themselves!