For friends who love car modification, it is very important to have a deep understanding of their car. Today we will focus on the unique construction of the Suzuki M13A engine and how to optimize the power through the high-performance piston assembly.

Reveal the unique structure and performance potential of Suzuki M13A engine

The M13A engine is known for its compact design and efficient work efficiency. This inline four-cylinder engine is equipped with a multi-point fuel injection system, which provides strong power while also taking into account economy. However, with the progress of technology and the change of driving demand, the original configuration may not be able to meet the desire of some users to pursue higher performance.

Why Choose a High Performance Piston Assembly? Explaining Key Benefits

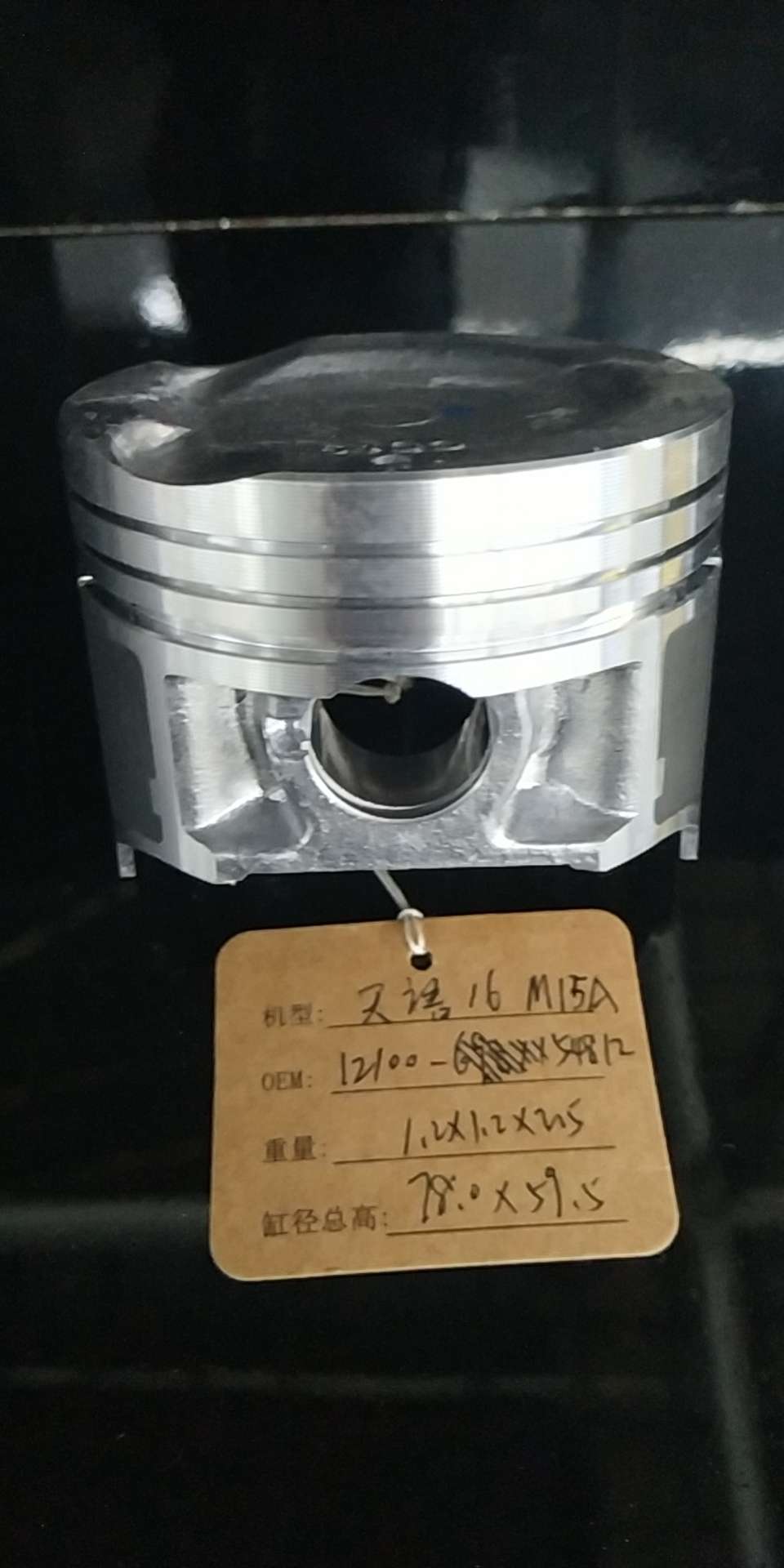

If you want to further explore the potential of the M13A engine, it is particularly necessary to replace a set of high-quality piston total achievements. The new model is produced by advanced manufacturing processes, with higher strength, better heat resistance and lower mass distribution characteristics. These improvements make the entire combustion process more smooth and efficient.

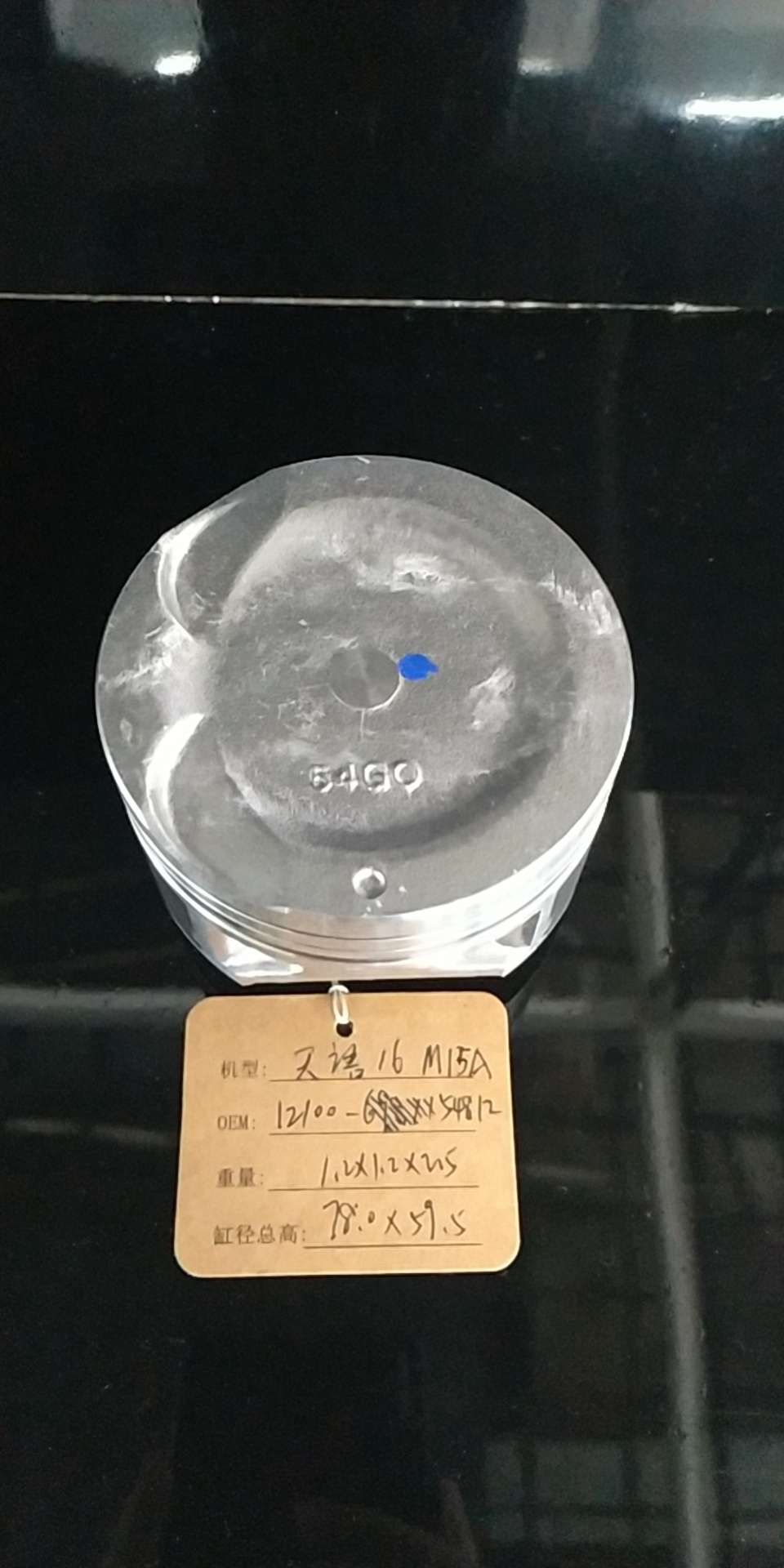

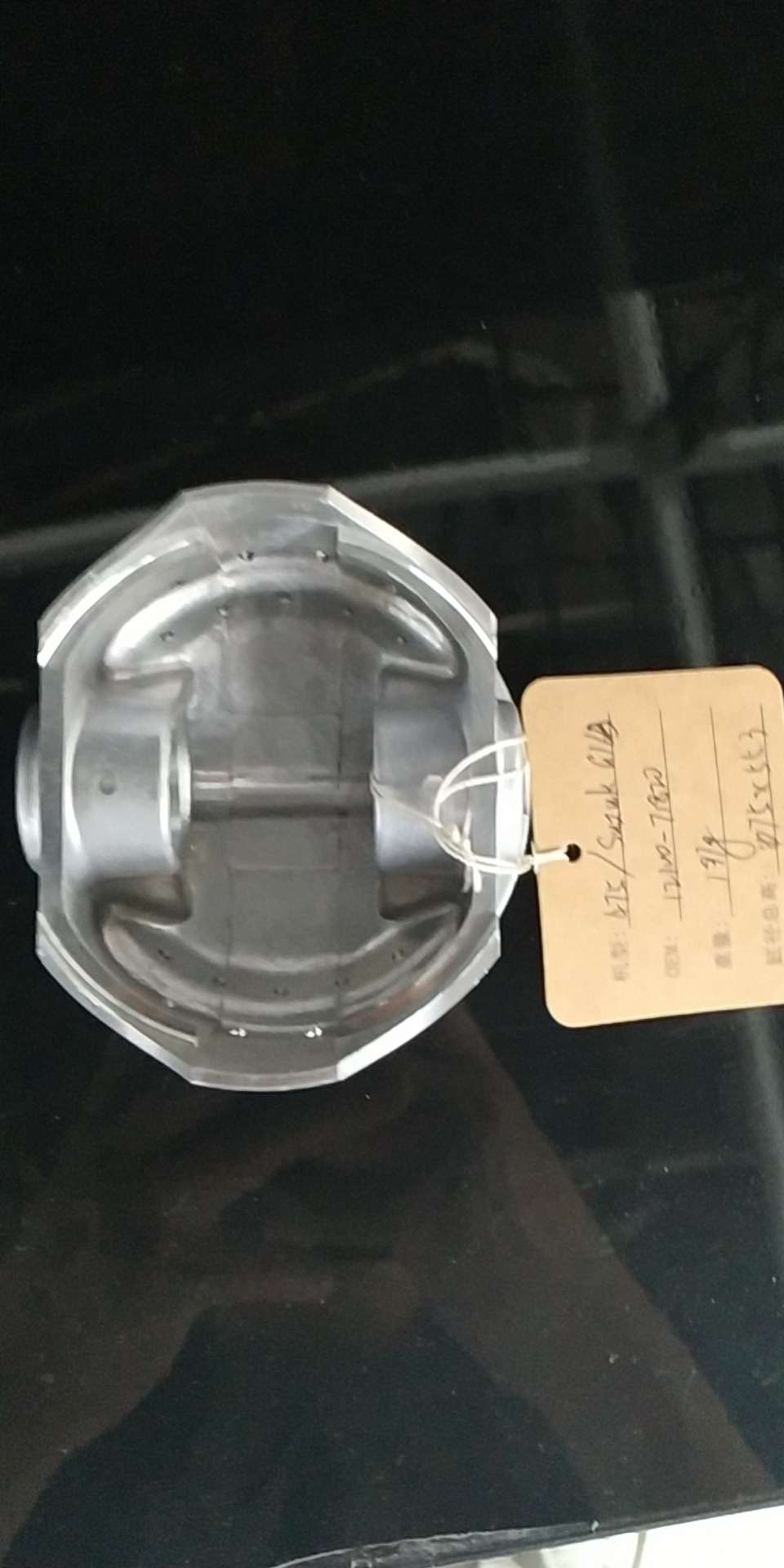

How to choose the most suitable piston material and technical specifications for M13A

several important parameters should be paid attention to in the process of purchasing. first, products made of aluminum alloy substrate mixed with carbon fiber reinforced particles are recommend selected in terms of material, because this composite profile can greatly increase durability on the basis of reducing weight. Secondly, regarding the setting of compression ratio, appropriate adjustments need to be made according to personal car usage habits-friends who like intense driving can choose a slightly higher value in exchange for a larger horsepower output value.

Actual Case Study: Data Display of Upgraded Power Improvement

In order to verify the practical effect of the above theory, we selected a standard version of Swift Sport modified with a new piston set for testing and comparison experiments. The results show that under the same conditions, the new components can increase the maximum power by about 15%, and shorten the acceleration time from 100 kilometers by nearly half a second! Such a remarkable achievement is enough to prove that the return on investment is considerable.

Installation considerations and maintenance recommendations to maximize service life

Although replacing parts seems simple and clear, there are still some details that cannot be ignored. For example, it is necessary to ensure that all connection parts are tight and correct, and the assembly procedures are completed in strict accordance with the instructions of the manual to avoid unnecessary damage. In addition, regular inspection of the quality of lubricating oil is also an indispensable part of ensuring long-term stable operation.

Summary of car owners' evaluation: real feedback reveals overall satisfaction

From the information collected from many car owners who have completed the modification project, everyone is generally satisfied with its performance. "The car feels much lighter when driving!" "Noise control is better and fuel consumption has not increased as much as expected." These are the most common voices of praise. It can be seen that as long as the right fitting and the correct operation method are selected, the expected results can be easily obtained ~