Suzuki M13A Engine Core Upgrade: Analysis of High Performance Piston Assembly

In the world of automotive performance, each part has a unique mission. The core component we are going to focus on today is the piston assembly of the Suzuki M13A engine. It is the soul of driving the vehicle forward and directly affects the power performance, fuel economy and overall operating efficiency.

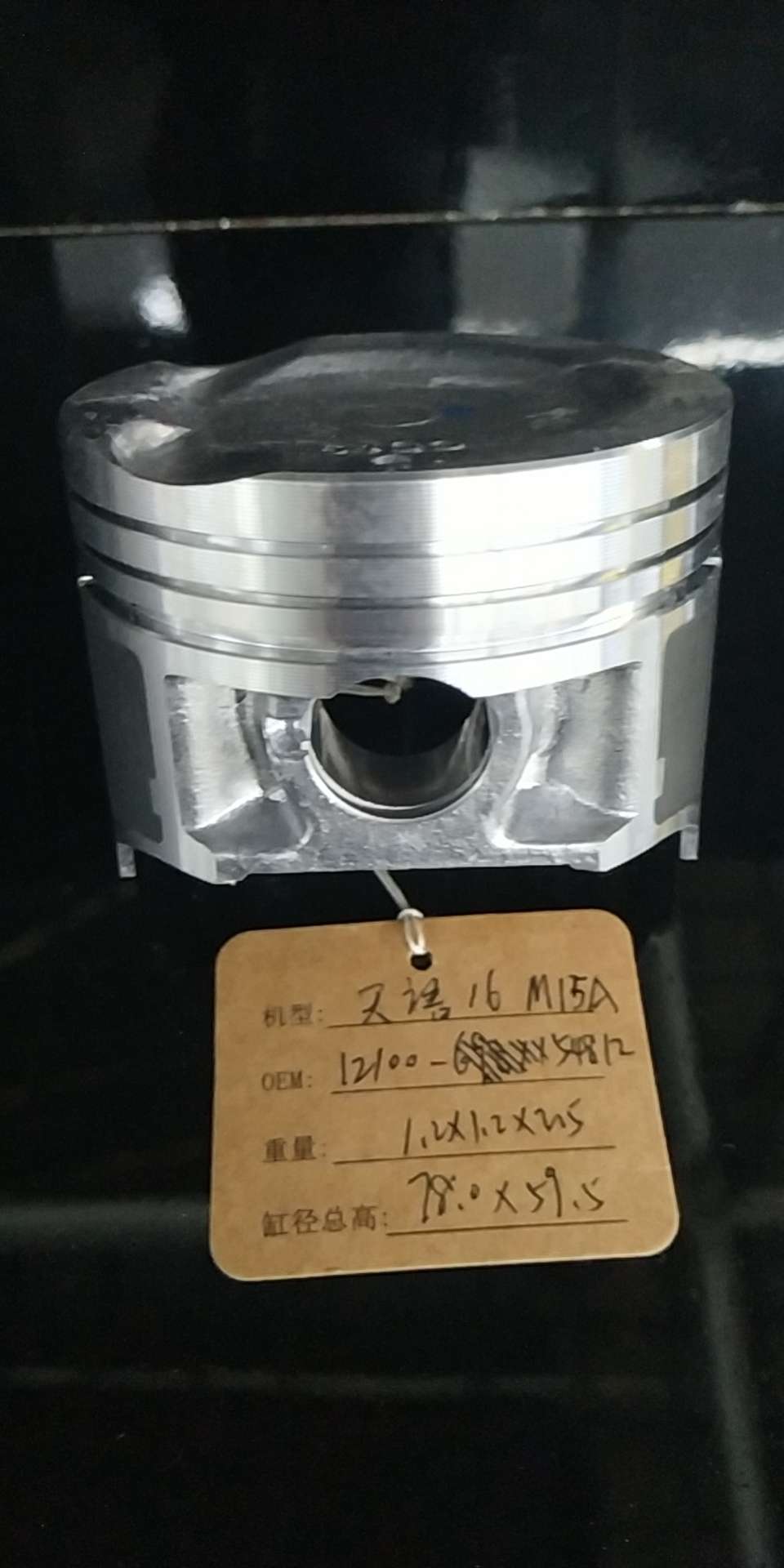

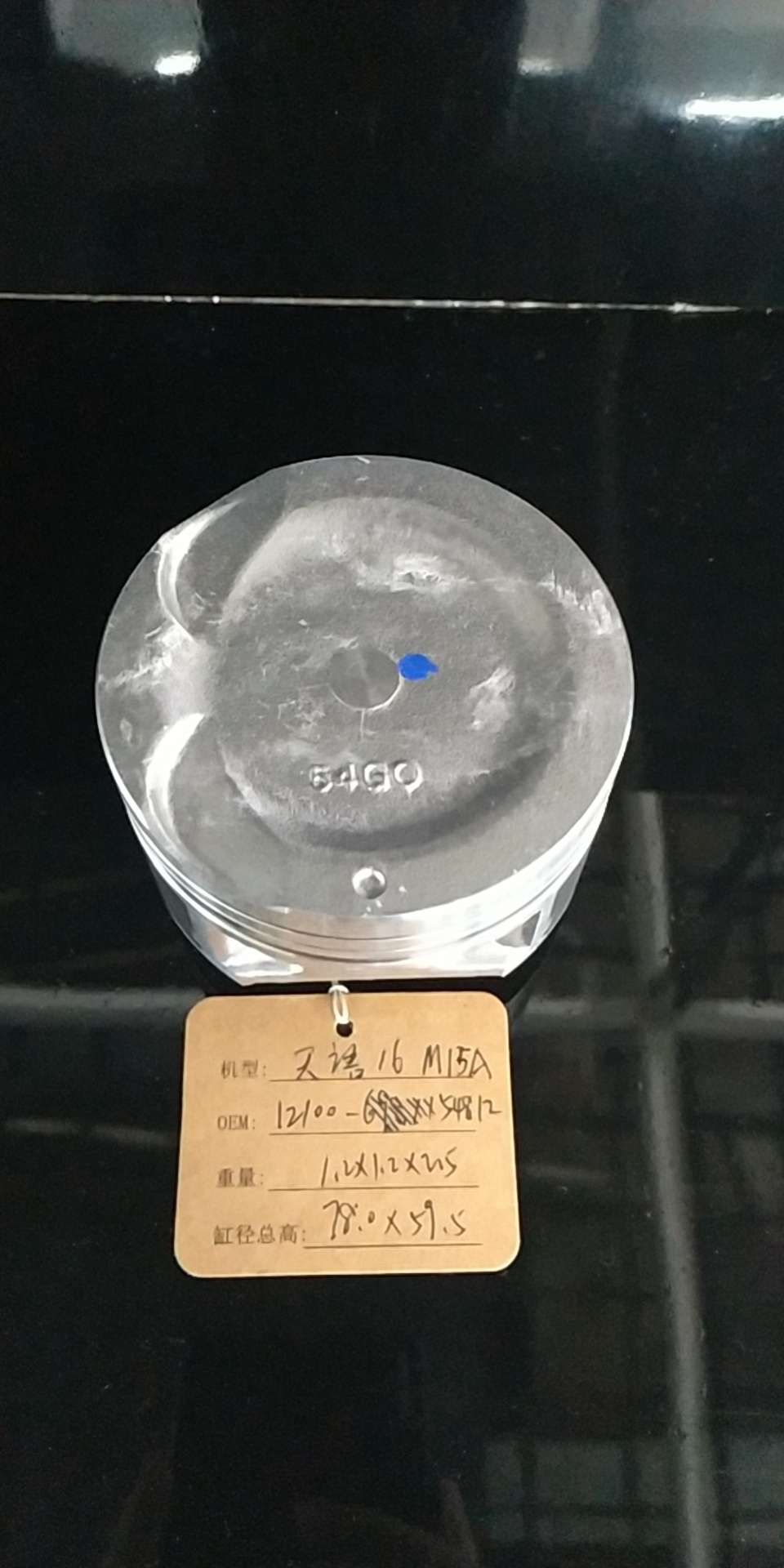

As a product designed to improve engine efficiency, the Suzuki M13A piston assembly is constructed using a range of cutting-edge technologies and carefully selected materials. It not only improves the pressure stability in the combustion chamber, but also significantly reduces energy loss, so that the vehicle accelerates more smoothly and powerfully.

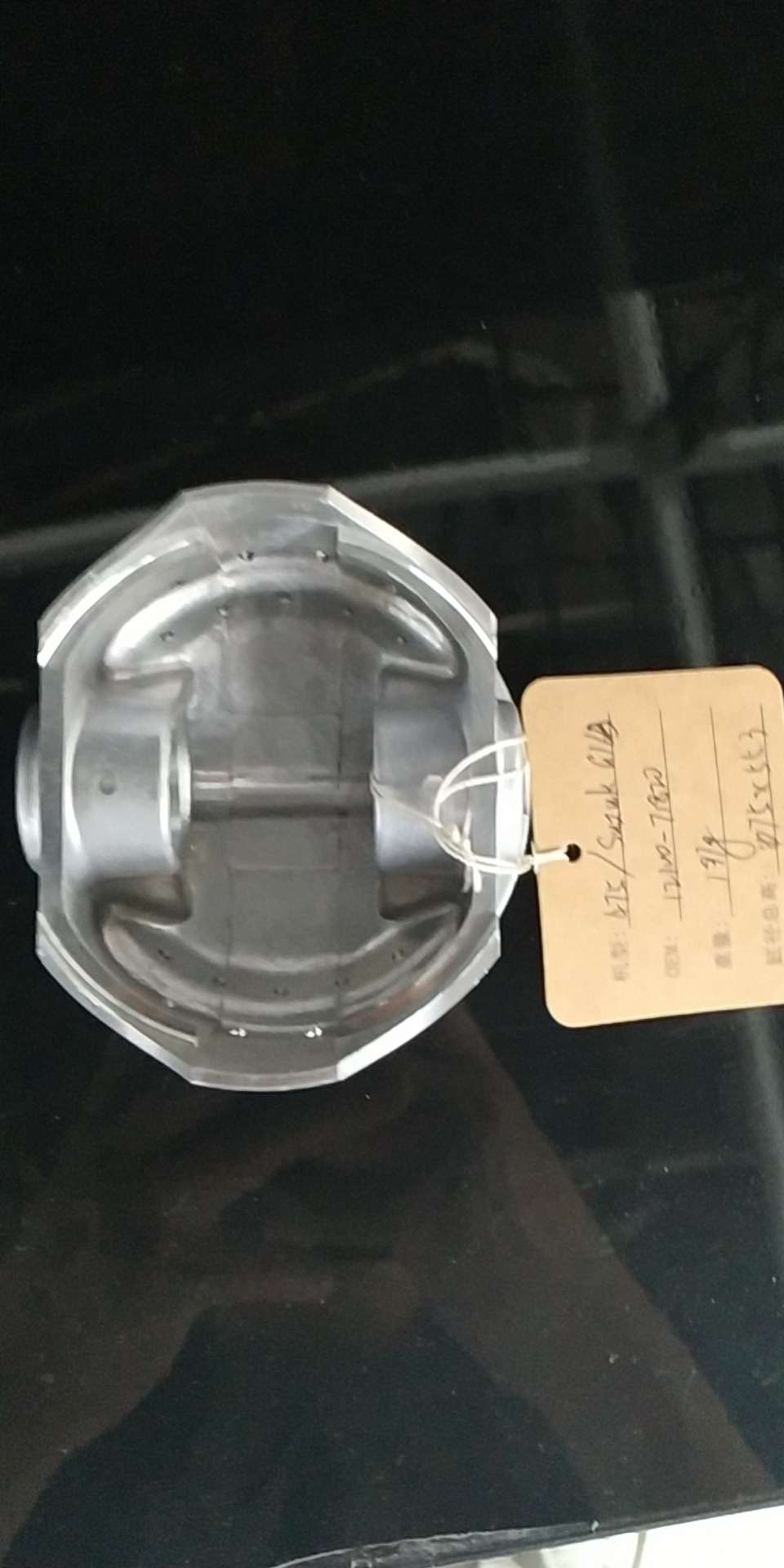

From raw material selection to precision machining process, every link is strictly controlled. For example, the application of high-strength aluminum alloy substrate makes the whole component have the advantages of light weight and wear resistance; at the same time, the surface coating technology further enhances the high temperature resistance and lubrication effect, and prolongs the service life.

For many car owners, "how to replace" may be one of their biggest concerns. In fact, thanks to the help of modular design concept, the new model has greatly simplified the assembly difficulty. Just follow the instructions to disassemble the old parts and replace the new ones in the corresponding parts to complete the whole operation process.

Not only that, this piston assembly has a wide range of compatibility, covering a variety of classic Suzuki models. Whether you are a city commuter who shuttles through busy city streets every day, or a professional off-road player who is keen to challenge the rugged mountain terrain, you can feel the obvious handling improvement experience through this improvement.

It is worth noting, however, that even the best technology requires proper maintenance to continue to function. To this end, we have compiled several practical suggestions for reference:

-Clean the air filter regularly to prevent dust particles from entering the cylinder and causing scratches.

-The use of genuine goods lubricants provided by regular channels ensures adequate protection of each moving contact surface.

-If abnormal noise or obvious increase in fuel consumption is found, it should be submitted for inspection in time to eliminate hidden dangers.

Finally, let's take a look at some positive comments from real users. "Since changing this equipment, the car has been driving much smoother!" A friend who has long been engaged in long-distance transportation business lamented. Another young consumer also said: "I used to feel a little sluggish when I started. Now I don't have this kind of worry at all." This feedback is undoubtedly the best proof of product quality.

In summary, if you are looking for a reliable way to rejuvenate your car, please don't hesitate to consider this Suzuki M13A high-performance piston assembly! Believe that it will not live up to your expectations.