Discover the secret weapon of the Suzuki M13A engine

The Suzuki M13A engine is known for its compact design and excellent fuel economy, making it an ideal source of power for many small cars. Inside this small but powerful machine, there is a crucial secret weapon-the piston assembly. As one of the heart parts of the engine, the piston assembly directly affects the operating efficiency and stability of the entire system. An in-depth understanding of its structure and working principle will not only enable us to better grasp the technical characteristics of this car, but also provide valuable guidance for future maintenance.

Full Analysis of Piston Assembly Structure

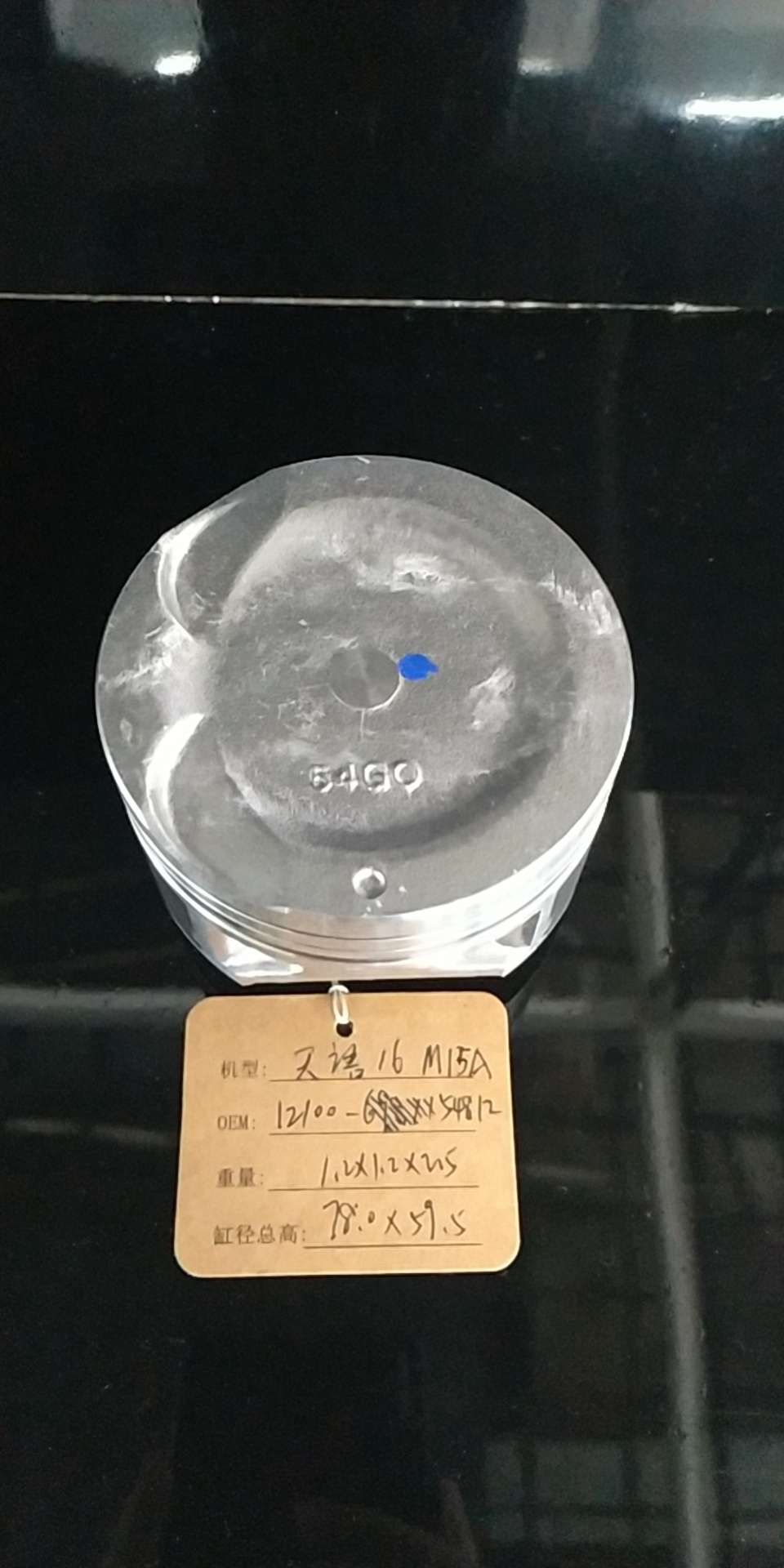

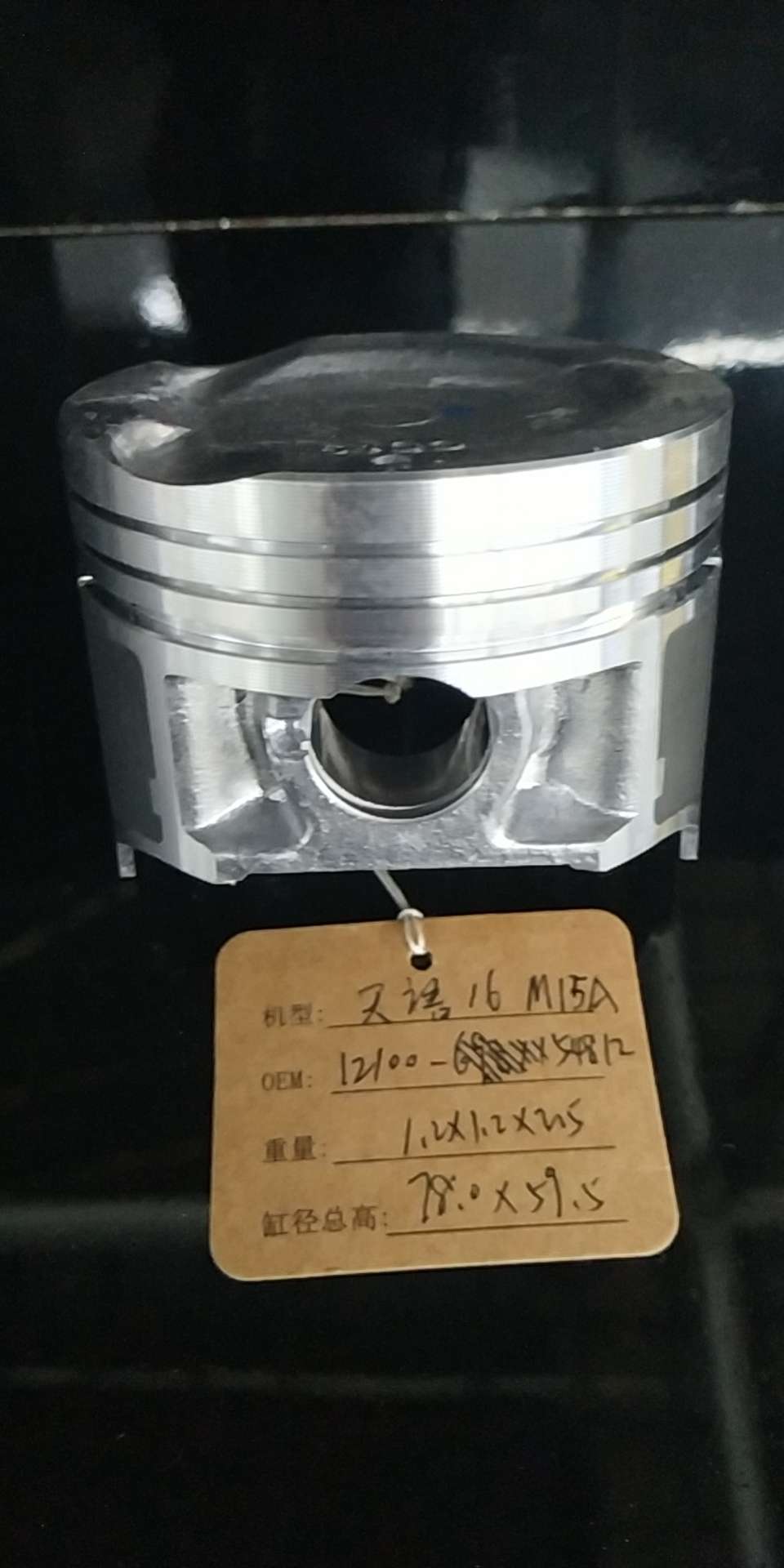

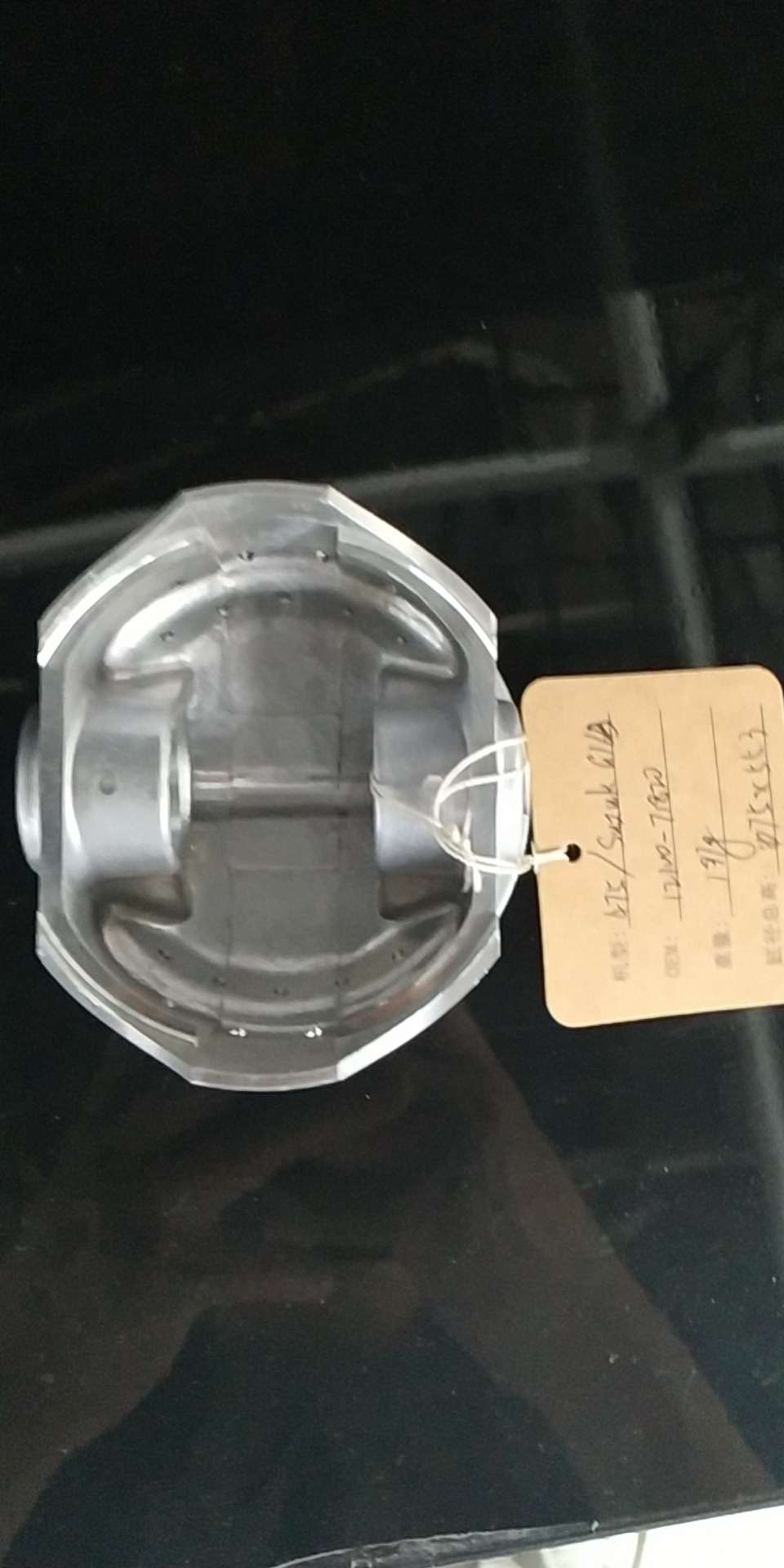

The piston assembly used by Suzuki M13A is composed of a number of precisely matched parts, including the piston itself, the piston ring and the important component connecting the crankshaft-the connecting rod. Each component plays an indispensable role in the combustion process. For example, the piston ring is mainly used to seal the cylinder wall gap to prevent the leakage of mixed gas; while the connecting rod is responsible for converting linear motion into rotary motion, thereby driving the vehicle forward. The following is a collaborative relationship between the main components:

The science behind efficient operation

The M13A series achieves higher thermal efficiency and lower emission standards through material selection and technology optimization. The application of the new aluminum alloy reduces the weight burden and enhances durability. In addition, advanced coating technology and improved piston skirt shape also help reduce friction losses, thereby improving fuel consumption performance. Through the comparison of real data, it is found that the average fuel consumption of vehicles equipped with the latest version of piston assembly has been reduced by about 0.5 litres per 100km, which fully reflects the progress brought about by science and technology.

Daily Maintenance Tips Open

In order to ensure that your car is always in good condition, please be sure to pay attention to the following aspects of maintenance points:

regularly check the quality of lubricating oil and liquid level height is very important, because high-quality oil can form an effective protective film in high temperature and high pressure environment.

when observed abnormal noise or power drop, should promptly check whether there is excessive wear problems, and the need to replace aging parts.

also need to pay special attention not to long time overload driving, so as not to cause unnecessary damage risk.

Upgrade feasibility assessment report

If you are eager to further explore the potential performance limits, you can consider making appropriate adjustments to the existing configuration. There are many high-performance alternatives designed for this model on the market to choose from, but before making a decision, it is still necessary to carefully weigh the input-output ratio and confirm whether you have enough professional knowledge to complete the installation and commissioning tasks. After all, any change may cause a chain reaction and even endanger driving safety, so it is recommended that the majority of users think twice.