If you want to rejuvenate your car while improving dynamic performance and lasting stability, replacing the high-performance pistons of the Suzuki M13A is an indispensable choice. As an important part of the heart of the vehicle, the piston assembly directly affects the performance of the entire machine.

Secret Suzuki M13A Core Power Source: Why Choose High Performance Piston Assembly

M13A series engines are widely praised for their excellent fuel economy and reliability. However, after long-term use, the original configuration may wear out, resulting in power drop and even frequent failures. At this point, the use of advanced replacement parts is particularly important. Our new piston assembly not only improves combustion efficiency, but also better responds to the high-intensity operation needs of complex road conditions.

Excellent quality analysis: a comprehensive interpretation from materials to processes

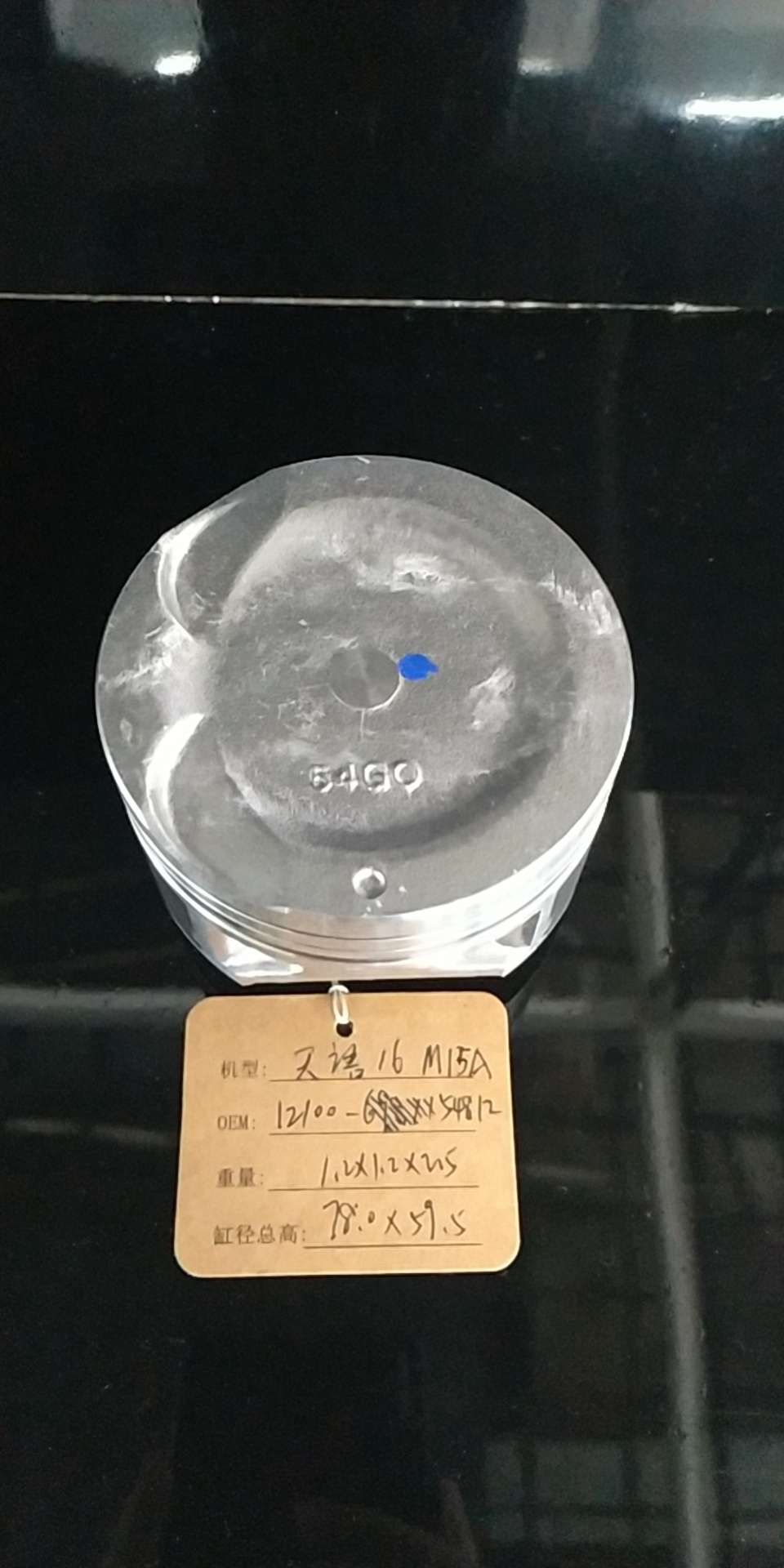

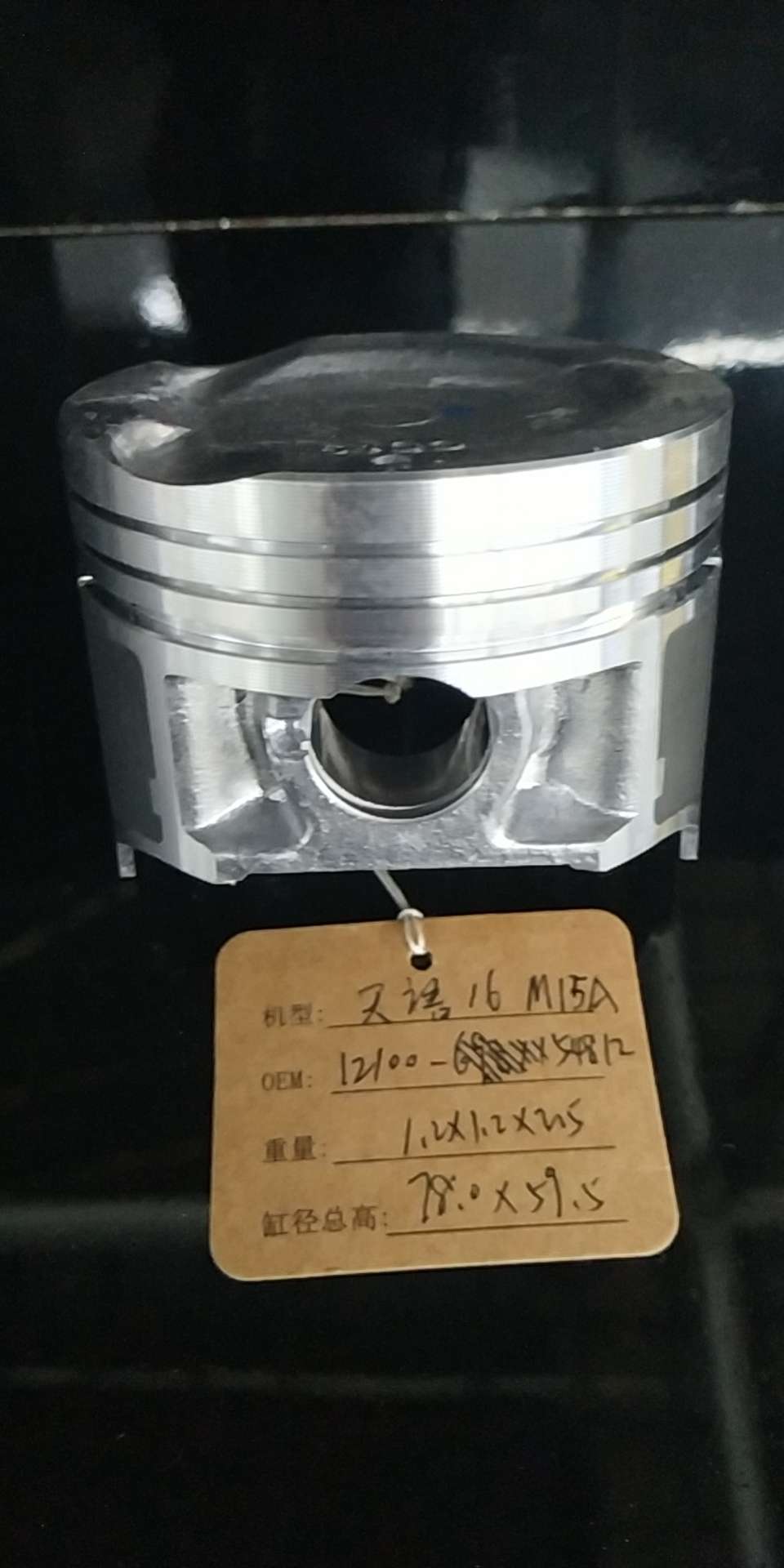

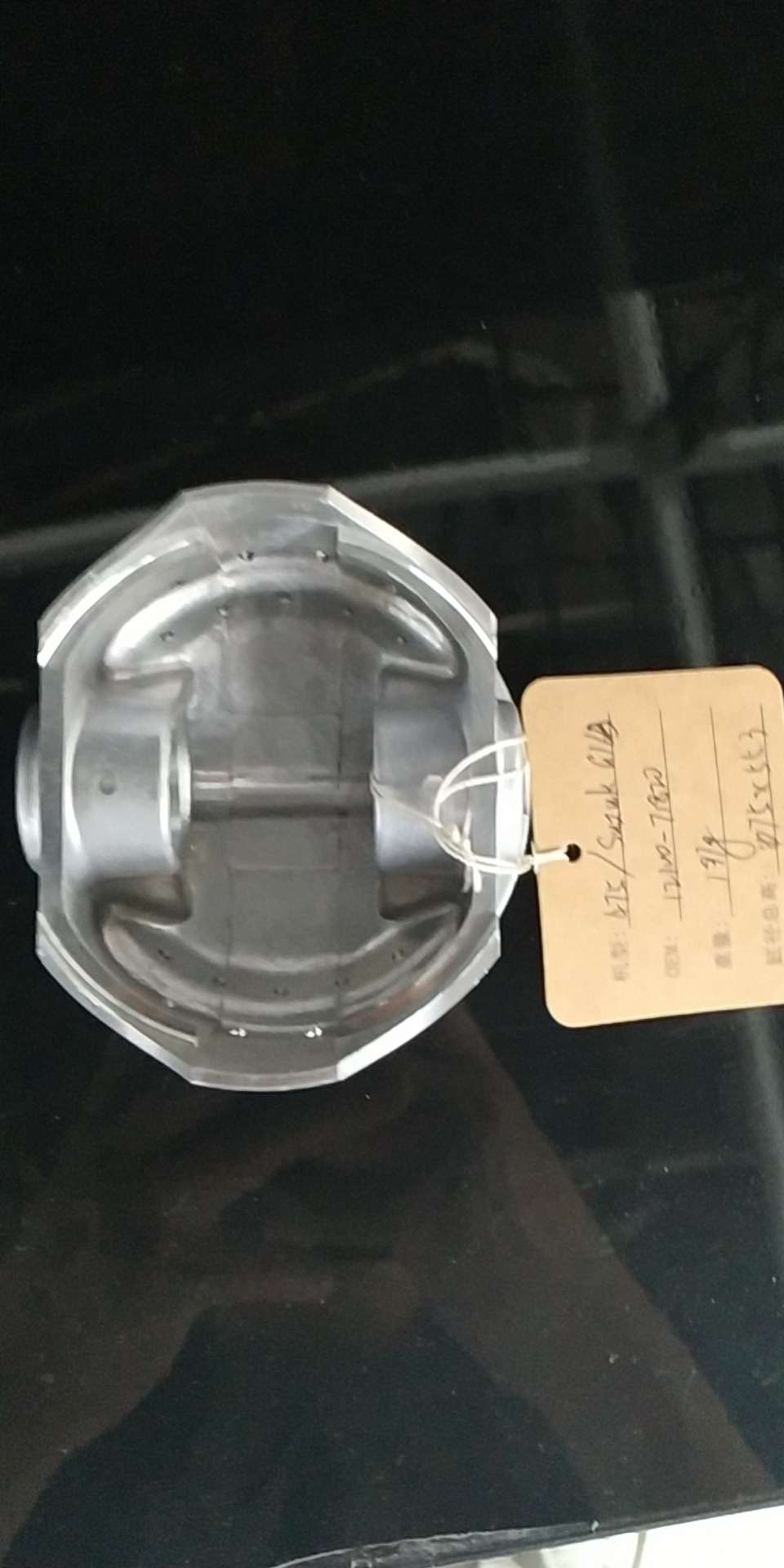

Behind every high-quality product is countless ingenuity. This piston is made of top aluminum alloy material, with excellent wear resistance and thermal deformation resistance; the surface is further enhanced by special anodic oxidation treatment. In addition, precision CNC machining ensures that the dimensional accuracy reaches the micron level, making the assembly gap more ideal, thereby reducing noise and extending service life.

Hands-on ability improvement time: step by step to teach you the correct installation of the piston assembly

In order to help car owners and friends successfully complete the modification task, here will introduce the whole process in detail:

The first step is to make full preparations before removing the old parts, including disconnecting the battery cable and recording the relevant parameter settings to prevent errors during reset.

Next, in accordance with the instructions to gradually remove the cylinder head bolts and crankshaft pulley components, and carefully pull out the spark plug socket so that subsequent operations smoothly.

and then there is the key link-cleaning the working area to avoid impurities mixed into the new parts, causing problems such as sticking, etc. Finally, all units are put back in turn until the initial form is restored.

Details determine success or failure: a key debugging link that cannot be ignored

Although the preparatory work has been very perfect, it is still necessary to pay attention to some details in order to ensure that the final effect is perfectly presented. For example, recalibrating whether the valve clearance value range meets the manufacturer's standard requirements, moderate amount of lubricating grease should not be too much, otherwise it may cause leakage risk, etc. are all tips that cannot be ignored ~

The Secret Weapon of Long-term Companion: recommend of Scientific and Reasonable Conservation Program

After completing the above steps, it does not mean that you can completely relax your vigilance! Regular professional care for new vehicles is also essential. It is suggested to go to the authorized service center for comprehensive physical examination items such as oil filter renewal, coolant stock replenishment and other work every certain mileage to maintain good operation and meet more challenges in the future.