Brand History

Suzuki Motor Company was established in 1920 and was initially engaged in the production and sales of textile machinery. Over time, Suzuki gradually transitioned into motorcycles and small cars, and quickly became a leader in both industries. Suzuki has won the trust of global consumers with its innovative technology and reliable products. Today, the Suzuki M13A piston assembly continues this tradition as the core component of its high-performance engine.

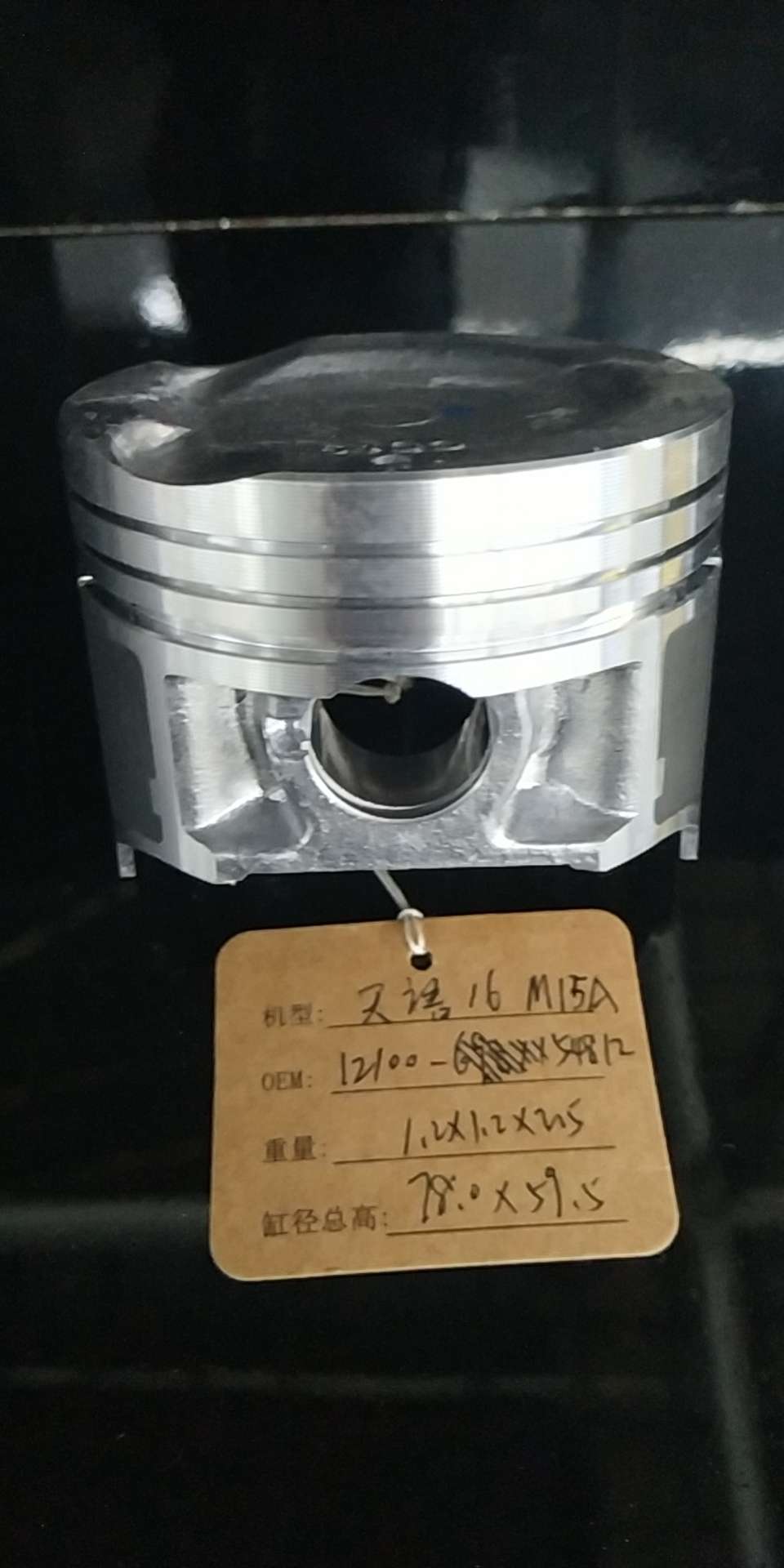

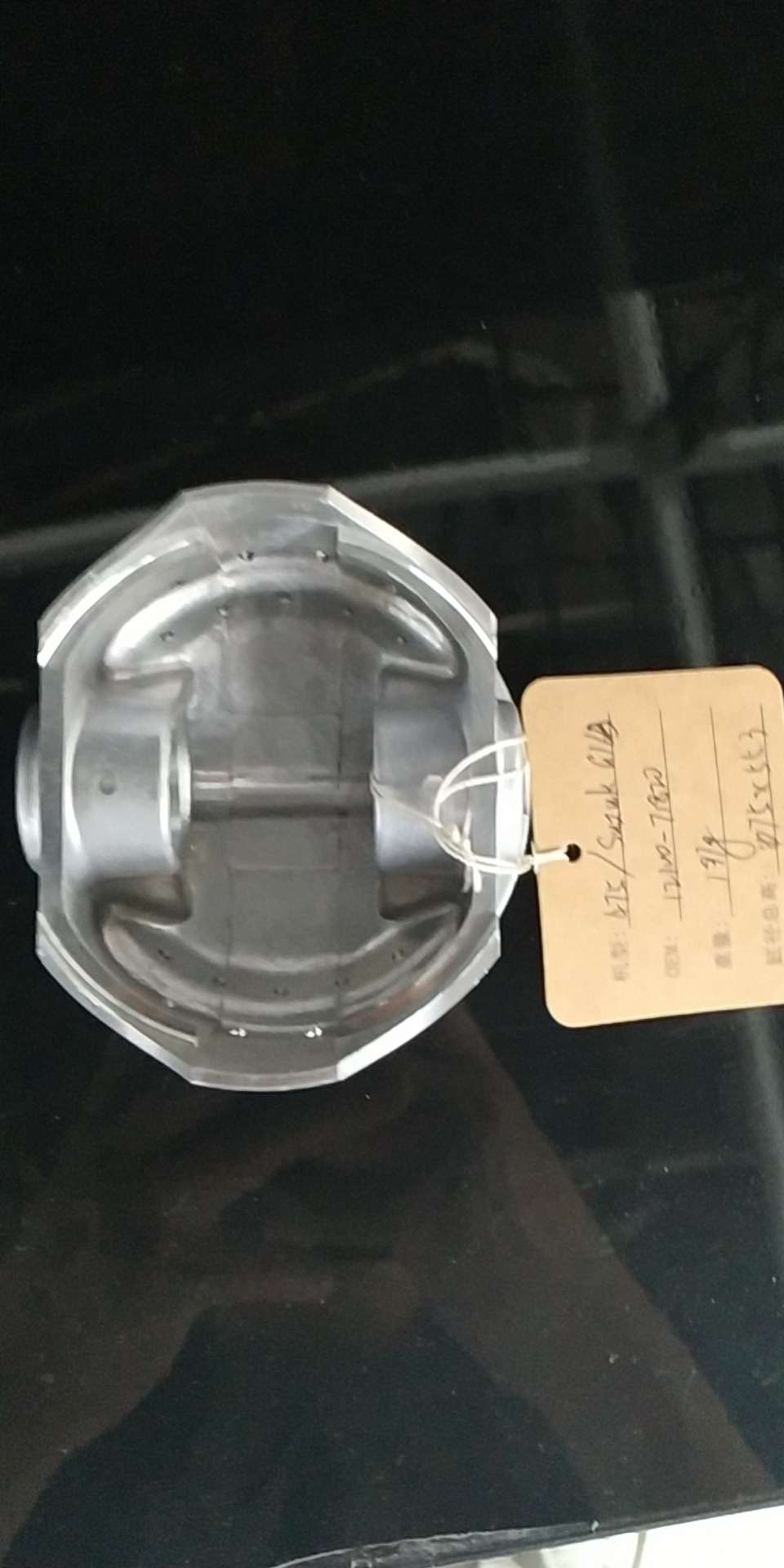

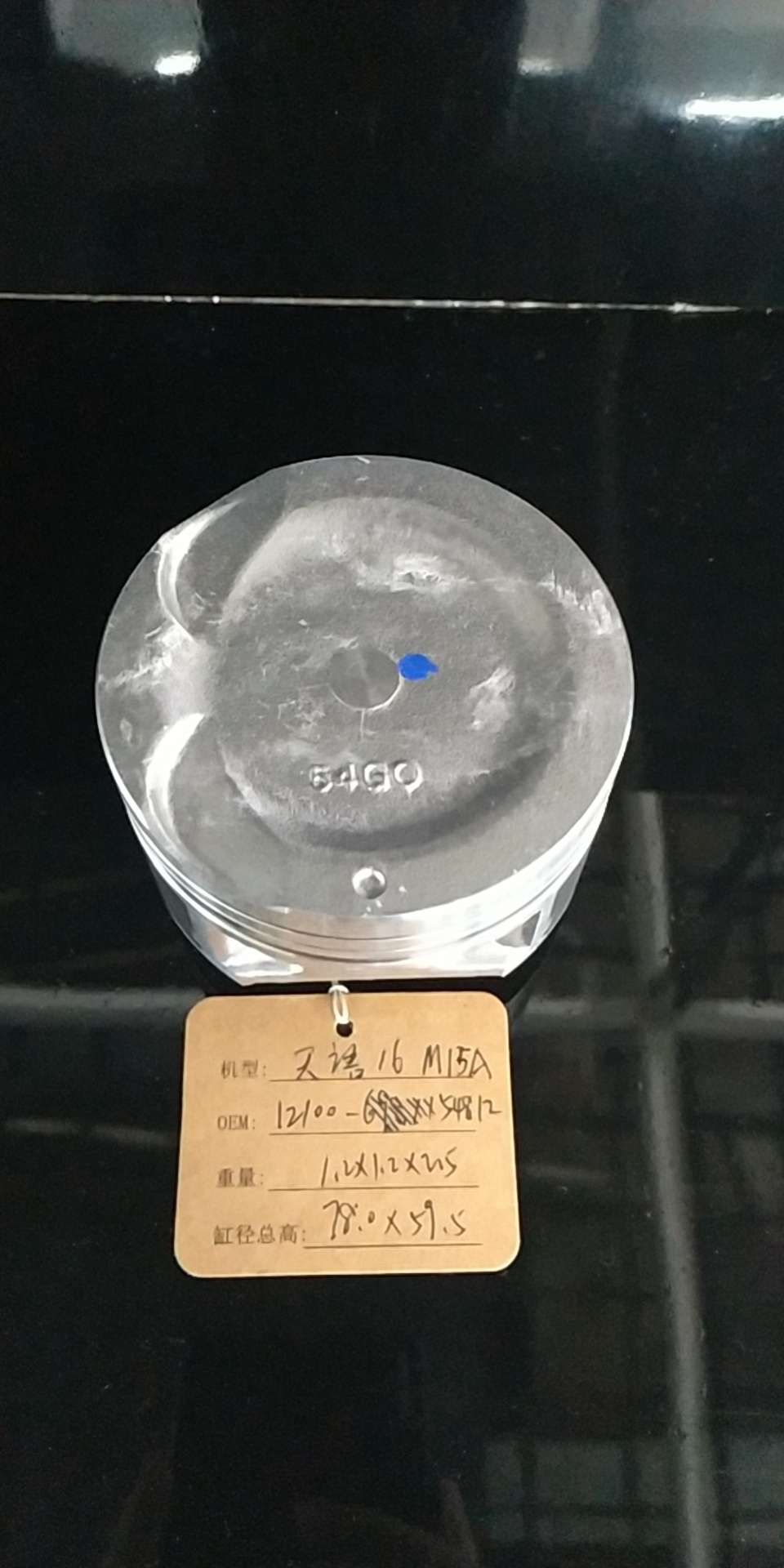

Product Overview

The Suzuki M13A engine is an efficient power system widely used in small cars. The engine uses a 1.3-liter displacement, four-cylinder design, with excellent fuel economy and strong power output. Among them, the piston assembly is one of the key components of the engine, which is responsible for converting the energy generated by fuel combustion into mechanical motion. The high-quality piston assembly can not only improve the performance of the engine, but also extend its service life.

Performance characteristics

The Suzuki M13A piston assembly is made of high-strength aluminum alloy material, which has undergone precision processing and strict testing to ensure the high precision and consistency of each component. This material has excellent high temperature resistance and wear resistance, and can maintain a stable working state even under extreme conditions. Through a number of tests and practical application verification, this piston assembly performs well in terms of power output and fuel economy, which can significantly improve the overall performance of the vehicle.

Installation steps

Installing the Suzuki M13A piston assembly requires technical and tool support. First, prepare the necessary tools, such as wrenches, screwdrivers and special disassembly tools. Next, follow the steps below:

1. Turn off the engine and wait for it to cool down.

2. Remove the cylinder head and related accessories.

3. Use special tools to remove the old piston assembly.

4. Clean the inside of the cylinder to ensure that there is no residue.

5. Install the new piston assembly, paying attention to the alignment mark.

6. Reinstall the cylinder head and other accessories.

7. Start the engine and check for leaks or other abnormalities.

In order to help users better understand and operate, we also provide high-definition pictures and video tutorials to ensure that each step is clear.

Maintenance

Regular maintenance and maintenance of the piston assembly is essential to ensure its long-term stable operation. The following are some basic maintenance suggestions:

1. **Cleaning**: Regularly clean the carbon deposits and impurities in the cylinder to prevent clogging.

2. **Lubrication**: Use high-quality oil and lubricating oil to ensure good lubrication between the piston and the cylinder wall.

3. **Inspection**: Regularly check the sealing of the piston ring and valve, and replace it in time if it is damaged.

4. **Maintenance cycle**: It is recommended to conduct a comprehensive inspection and maintenance every 10000 kilometers.

The correct maintenance method can not only extend the service life of the piston assembly, but also improve the overall performance of the engine.

Troubleshooting

Despite the superior performance of the Suzuki M13A piston assembly, some common failures may still occur during use. The following are some typical failure phenomena and their solutions:

1. **Difficulty in starting**: It may be due to insufficient compression caused by wear of the piston ring, and the piston ring needs to be replaced.

2. **Increased fuel consumption**: It may be due to the excessive gap between the piston and the cylinder wall, which causes the mixture to leak, and the piston needs to be adjusted or replaced.

3. **Abright noise**: It may be that the piston pin is loose or the bearing is worn, and the corresponding parts need to be tightened or replaced.

Through case analysis, we can help users discover and solve these problems in time to ensure the normal operation of vehicles.

User Story

For the reader