The Basics of the M13A Engine

The Suzuki M13A engine is a notable member of Suzuki's engine lineup, known for its reliability and efficiency. This inline-4 engine, with a displacement of 1.3 liters, is commonly found in various Suzuki models like the Swift and Ignis. It is renowned for its balance of performance and fuel economy, making it a popular choice for both everyday commuting and spirited driving.

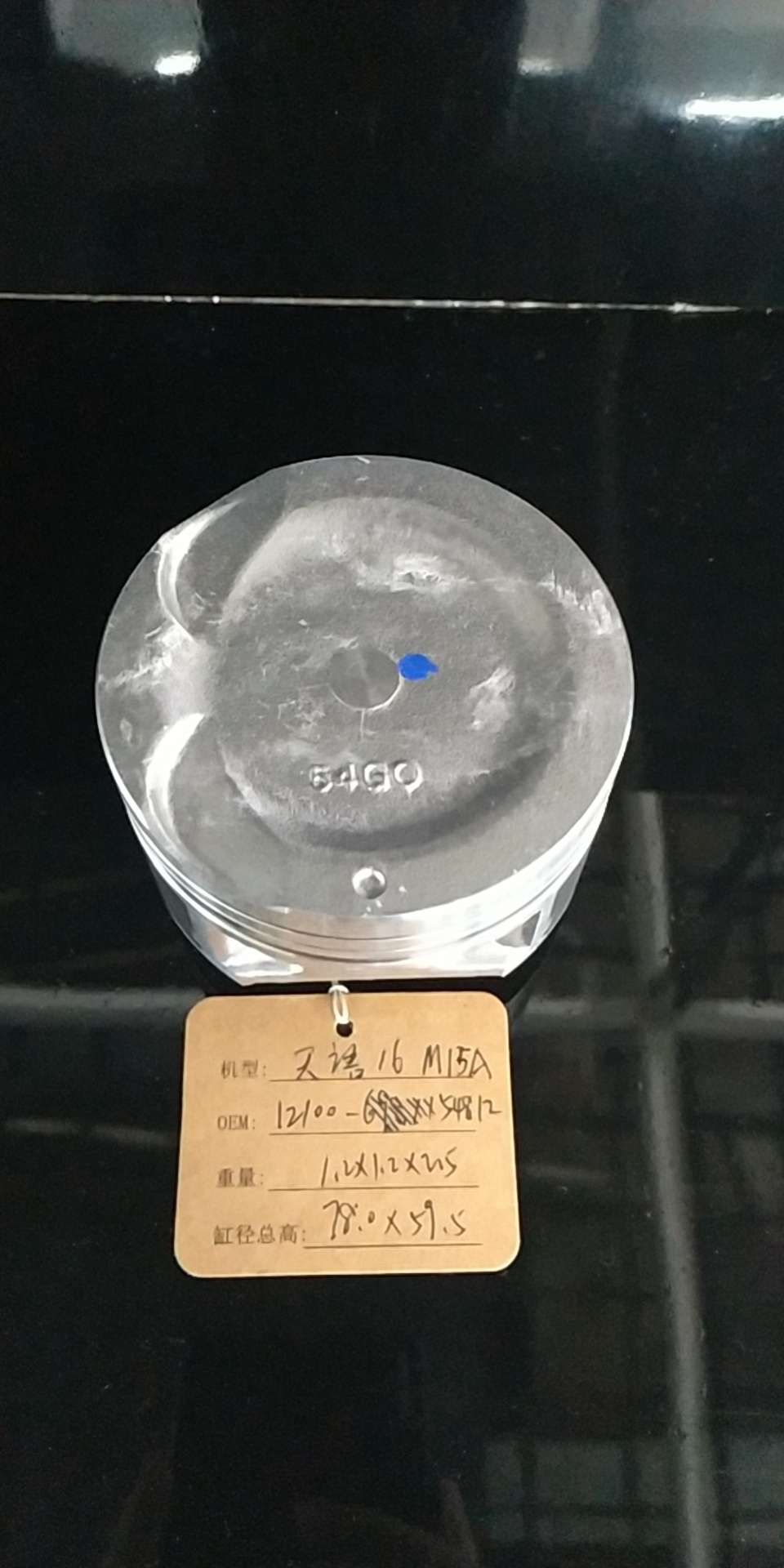

Key specifications of the M13A include a bore and stroke of 78.0 mm and 69.5 mm, respectively, and a compression ratio of 9.5:1. This engine utilizes an aluminum alloy block and cylinder head, which contributes to its lightweight and efficient design.

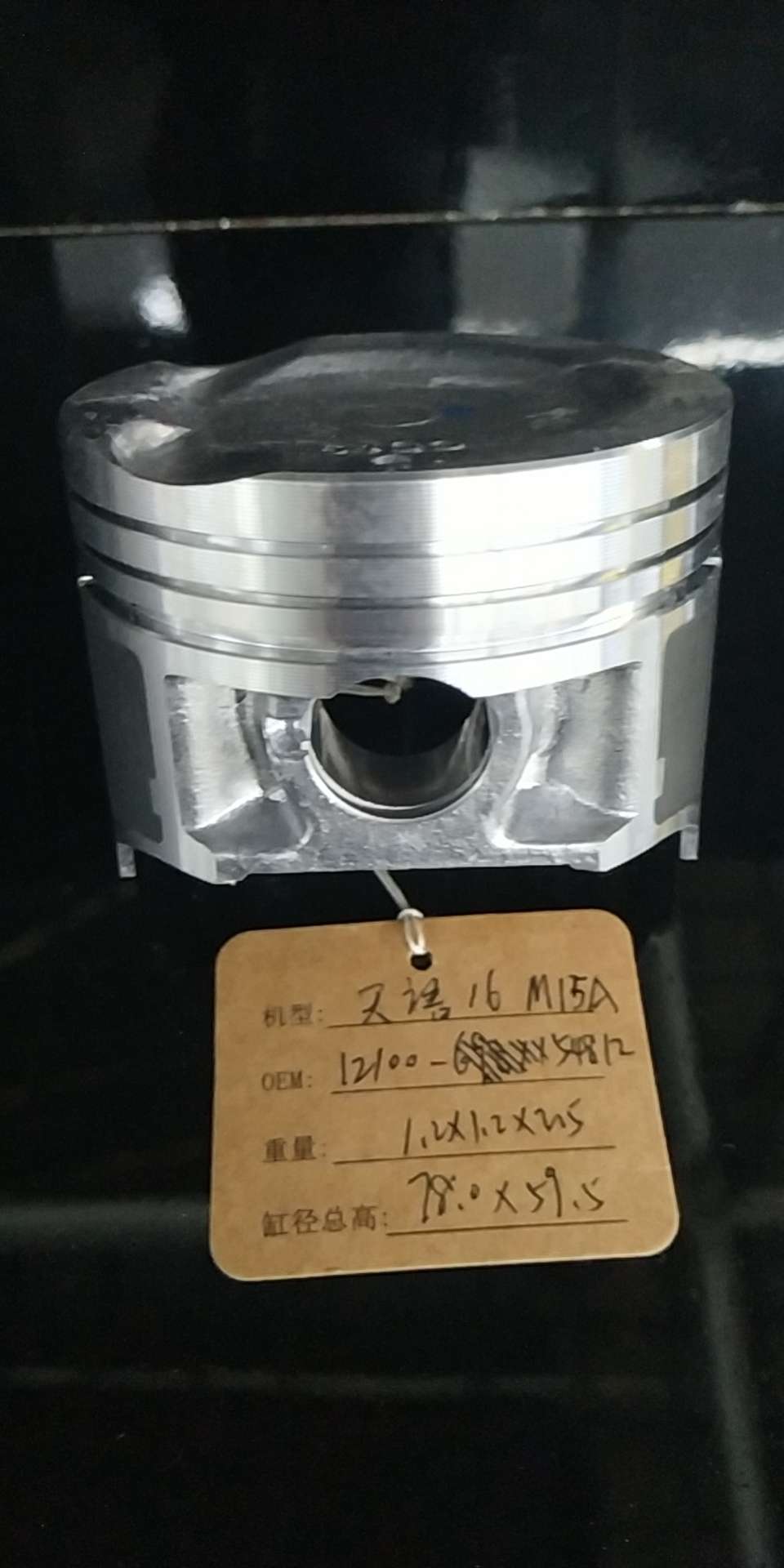

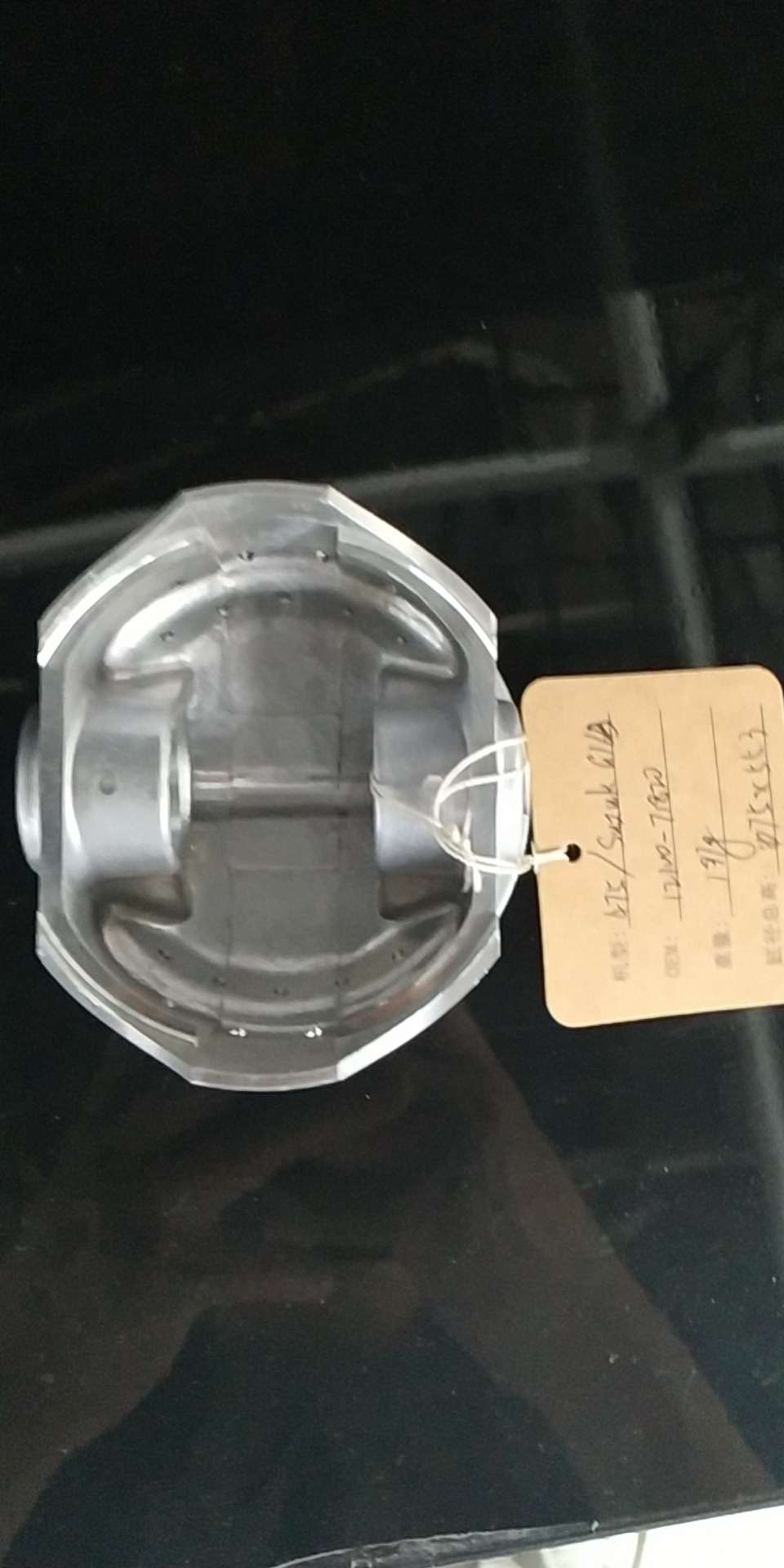

Anatomy of the Piston Assembly

The piston assembly is a crucial component of the M13A engine, comprising several key parts that work together seamlessly:

- Piston: The piston is the main component that moves up and down within the cylinder, converting the energy from combustion into mechanical motion.

- Piston rings: These rings provide a seal between the piston and cylinder wall, maintaining compression and reducing oil consumption.

- Connecting rod: This rod connects the piston to the crankshaft, translating the piston's linear motion into rotational motion.

- Wrist pin: Also known as the gudgeon pin, it connects the piston to the connecting rod, allowing for pivoting movement.

Materials used in manufacturing these components typically include high-strength alloys to withstand the intense conditions within the engine.

Functionality and Role in Engine Operation

The piston assembly plays a vital role in the M13A engine's operation. As the engine runs, the pistons move up and down within the cylinders in a precise sequence. This movement is driven by the combustion of the air-fuel mixture, which generates the force needed to push the pistons downward. The connecting rods then transmit this force to the crankshaft, converting it into rotational motion that ultimately powers the vehicle.

Pistons are integral to the internal combustion process, directly affecting engine performance and efficiency. A well-functioning piston assembly ensures optimal compression, leading to better power output and fuel economy.

Common Issues and Maintenance Tips

Like any mechanical component, the piston assembly is subject to wear and tear. Common signs of wear include increased oil consumption, loss of compression, and unusual engine noises. If you notice any of these symptoms, it's essential to troubleshoot the problem promptly.

Regular maintenance can significantly extend the life of your piston assembly. This includes using high-quality engine oil, adhering to recommended oil change intervals, and ensuring proper engine tuning. Keeping the engine clean and free of debris also helps maintain optimal piston function.

Upgrading and Replacement

There are several signs that indicate a need for piston assembly replacement, such as persistent knocking sounds, visible damage during inspection, or significantly reduced engine performance. When upgrading or replacing the piston assembly, it's crucial to follow a systematic approach:

- Identify the correct replacement parts for your specific engine model.

- Gather the necessary tools, such as a torque wrench, piston ring compressor, and engine hoist.

- Carefully disassemble the engine, taking note of the orientation and placement of each component.

- Install the new piston assembly, ensuring all components are properly fitted and torqued to specification.

Using high-quality parts, like those offered by Yiwu Jucheng Auto Parts Co., LTD, ensures reliability and performance.

Performance Enhancements and Modifications

For those looking to enhance engine performance, several aftermarket options are available for the M13A piston assembly. Upgraded pistons, high-performance rings, and lightweight connecting rods can all contribute to improved engine dynamics.

However, it's important to weigh the pros and cons of various modifications. While performance parts can offer significant gains, they may also increase stress on other engine components and require more frequent maintenance.

Case studies of successful piston assembly upgrades often highlight the benefits of careful planning and professional installation, resulting in notable improvements in power and efficiency.

Expert Tips and Tricks

Professional mechanics offer valuable advice for working with piston assemblies. Key tips include:

- Always use a ring compressor when installing pistons to prevent damage to the rings and cylinder walls.

- Ensure proper lubrication of all moving parts during assembly to reduce friction and wear.

- Double-check all torque specifications to prevent loose or overtightened bolts.

Avoiding common pitfalls, such as improper ring gap alignment or incorrect piston orientation, can enhance the longevity and performance of your engine.

Resources and Further Reading

For those seeking additional information on the Suzuki M13A piston assembly, several resources are available:

- Manufacturer's manuals and service guides provide detailed instructions and specifications.

- Online forums and communities offer a platform for sharing experiences and troubleshooting tips.

- Video tutorials and instructional content can provide visual guidance for complex procedures.

By leveraging these resources, you can gain a deeper understanding of your engine and ensure optimal performance.