For many drivers, the car is not only a means of transportation, but also a manifestation of a way of life. Among many models, vehicles equipped with Suzuki M13A engines are favored for their excellent fuel economy and reliability. Today we will focus on the core component of this classic engine-M13A piston assembly , and take you to understand its technical characteristics and maintenance points.

Exploring the heart of the M13A engine: deciphering the key functions of the piston assembly and its importance

As the heart of the engine, the role of the piston assembly cannot be underestimated. It is responsible for converting the energy generated by combustion into mechanical motion, thus driving the operation of the entire power system. Specifically:

- -Precise control of compression ratio;

- -Improve fuel efficiency;

- -Extend engine life.

By carefully polishing every detail, this part not only ensures efficient operation, but also greatly reduces the risk of wear.

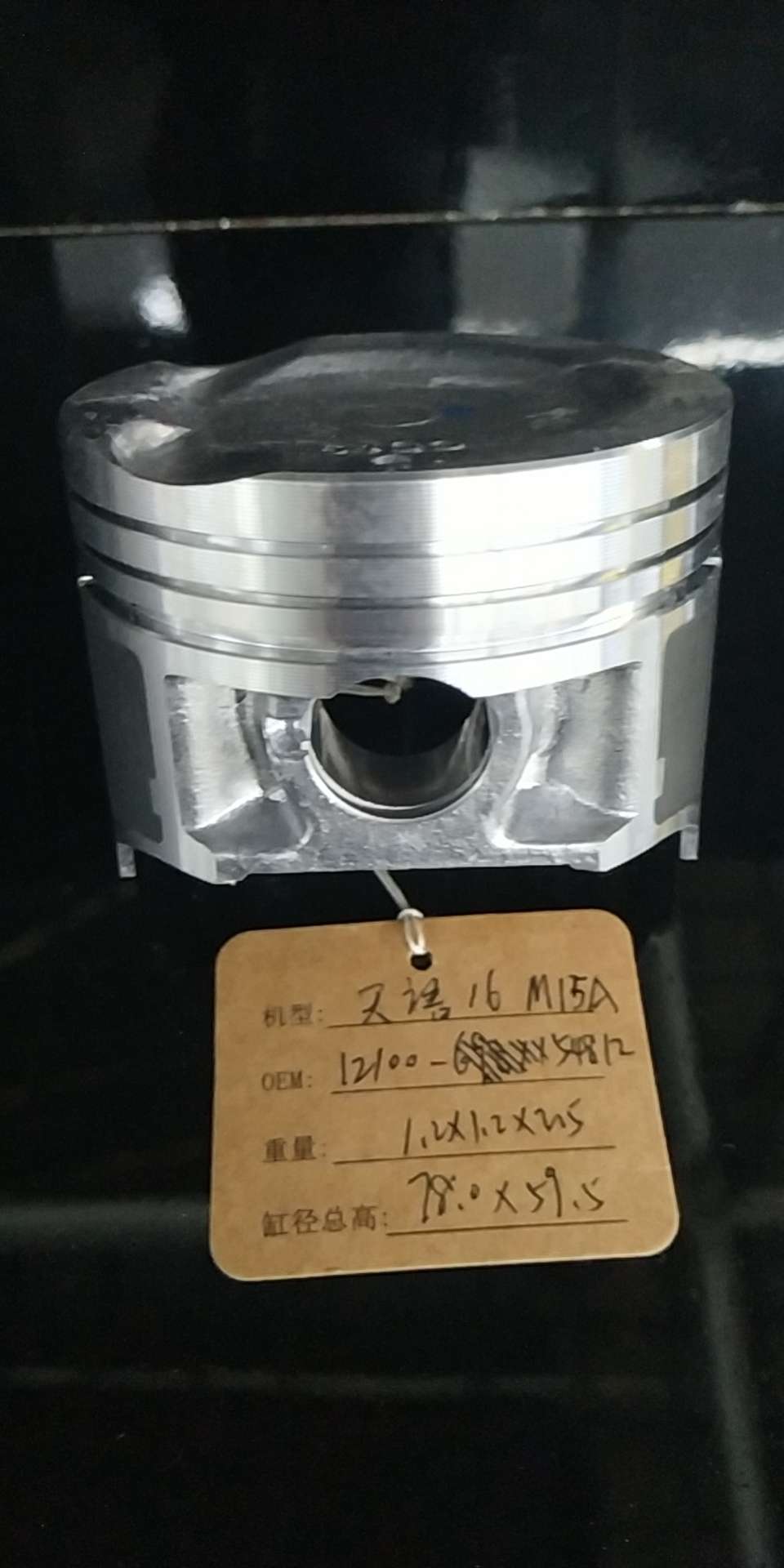

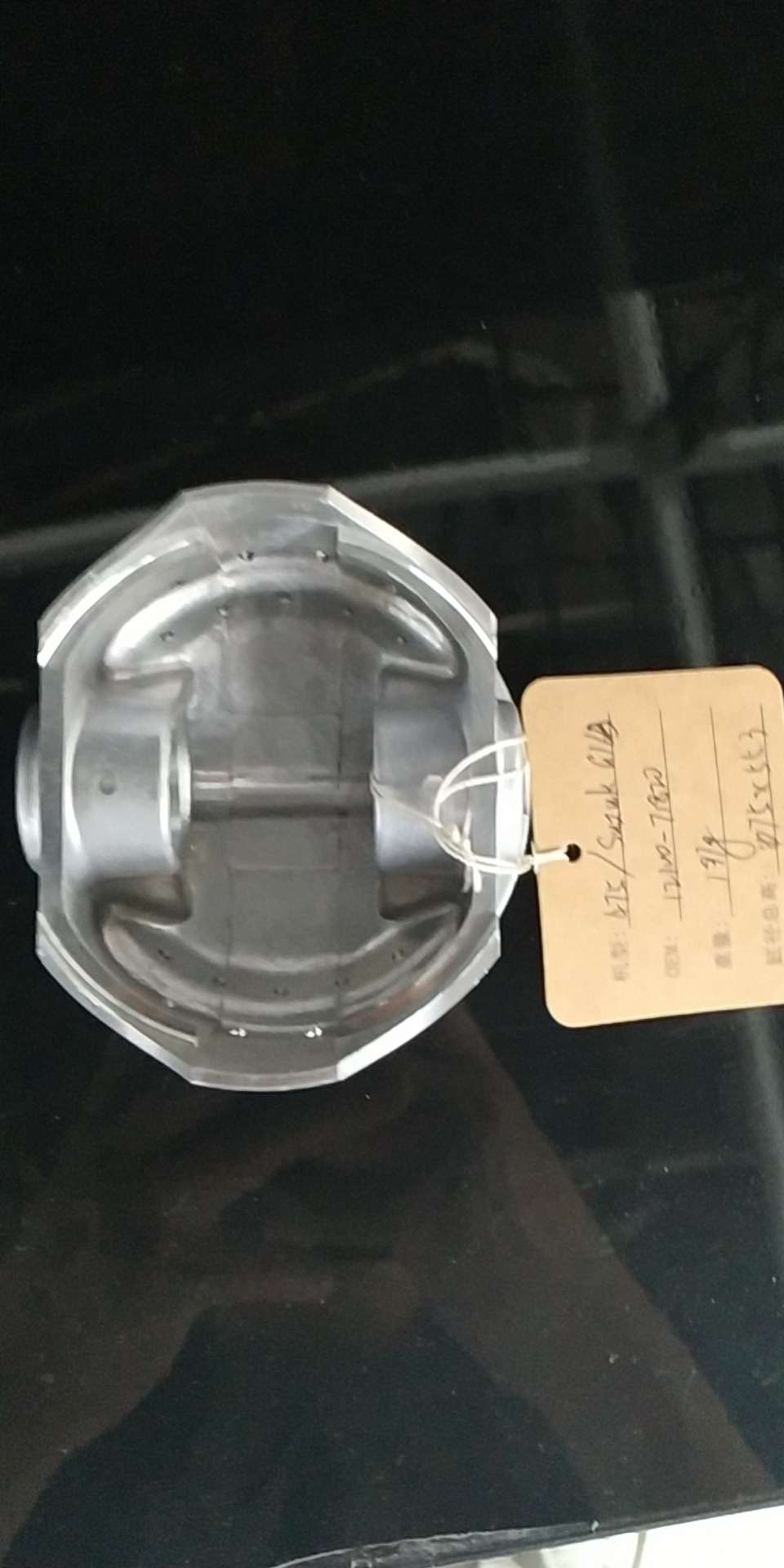

Technical analysis: detailed explanation of the design features and innovations of Suzuki M13A piston assembly

Compared with the traditional design, Suzuki engineers have made many improvements to the M13A:

first , the material selection is made of higher strength alloy steel, which significantly enhances the ability of high temperature resistance and corrosion resistance; secondly, the skirt shape is specially optimized-more streamlined profile reduces friction resistance and improves the sealing effect.

In addition, it is worth mentioning that the new generation of products introduces advanced coating technology, which can further reduce the surface roughness value and increase the wear resistance coefficient. It is these small but crucial adjustments that create a more stable and powerful power source!

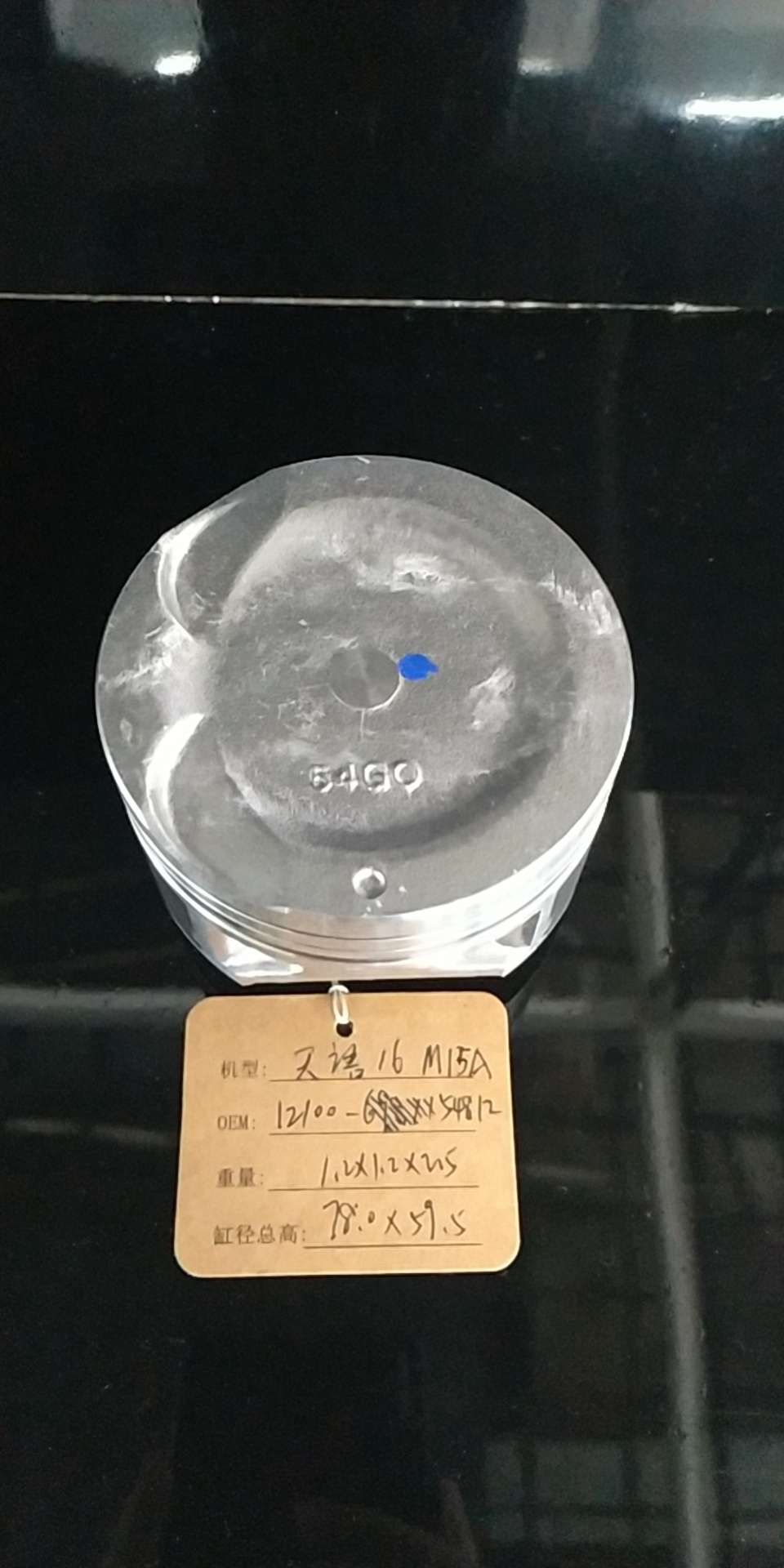

The choice of quality: how to judge the quality of a high-quality piston assembly standard

When faced with a wide variety of products on the market, how do you choose the one that really suits your car? The following points can help you quickly distinguish between good and bad:

- -whether there is a complete authentication mark (e. g. OE number matching);

- -whether the surface color is uniform and flawless;

- -Whether the dimensional tolerance range meets the original specifications;

- -Installation manual and spare parts list integrity check are included in the package.

only after comprehensive consideration before making a decision can avoid subsequent troubles to the greatest extent ~

Maintenance Secrets: Correct Maintenance Methods Make Your Car Glow with Long-term Power and Vitality

even if you have top-quality accessories, you need to take care of them regularly! The following suggestions may help all car owners:

(1) regularly replace the oil filter to maintain the clean state of the lubrication system;

(2) avoid long-term idling operation to avoid excessive carbon deposits affecting the normal work flow;

(3) if abnormal sound is found, send it for inspection and investigation of potential hidden dangers.

Practical Experience Sharing: Real User Cases Reveal Efficient Replacement Skills and Precautions

Mr. Zhang, a veteran DIY enthusiast, noticed a slight shake in his car during a routine overhaul. The diagnosis of professional technicians confirmed that the old piston ring aging caused by poor sealing. Therefore, he decisively purchased a new set of special substitutes for Suzuki to complete the update operation by himself.

during this period, I summarized some valuable experiences:

"before disassembly, be sure to mark and record the position sequence of each screw to prevent confusion and problems in the assembly process."

at the same time remind the majority of peers, "the whole operation must wear protective gloves and ensure that all tools are fully prepared before starting the construction steps".

All in all, as long as you follow scientific guidelines and have a careful and patient attitude, you can easily solve similar problems! I hope the above information is helpful to you ~