In the automotive field, the engine is called the "heart", and the piston assembly plays a vital role. Today we will uncover the secret of one of the core components of the Suzuki M13A engine- piston assembly , and see how it helps achieve strong power and efficient operation.

Secret of the heart of the Suzuki M13A engine: the importance of the piston assembly

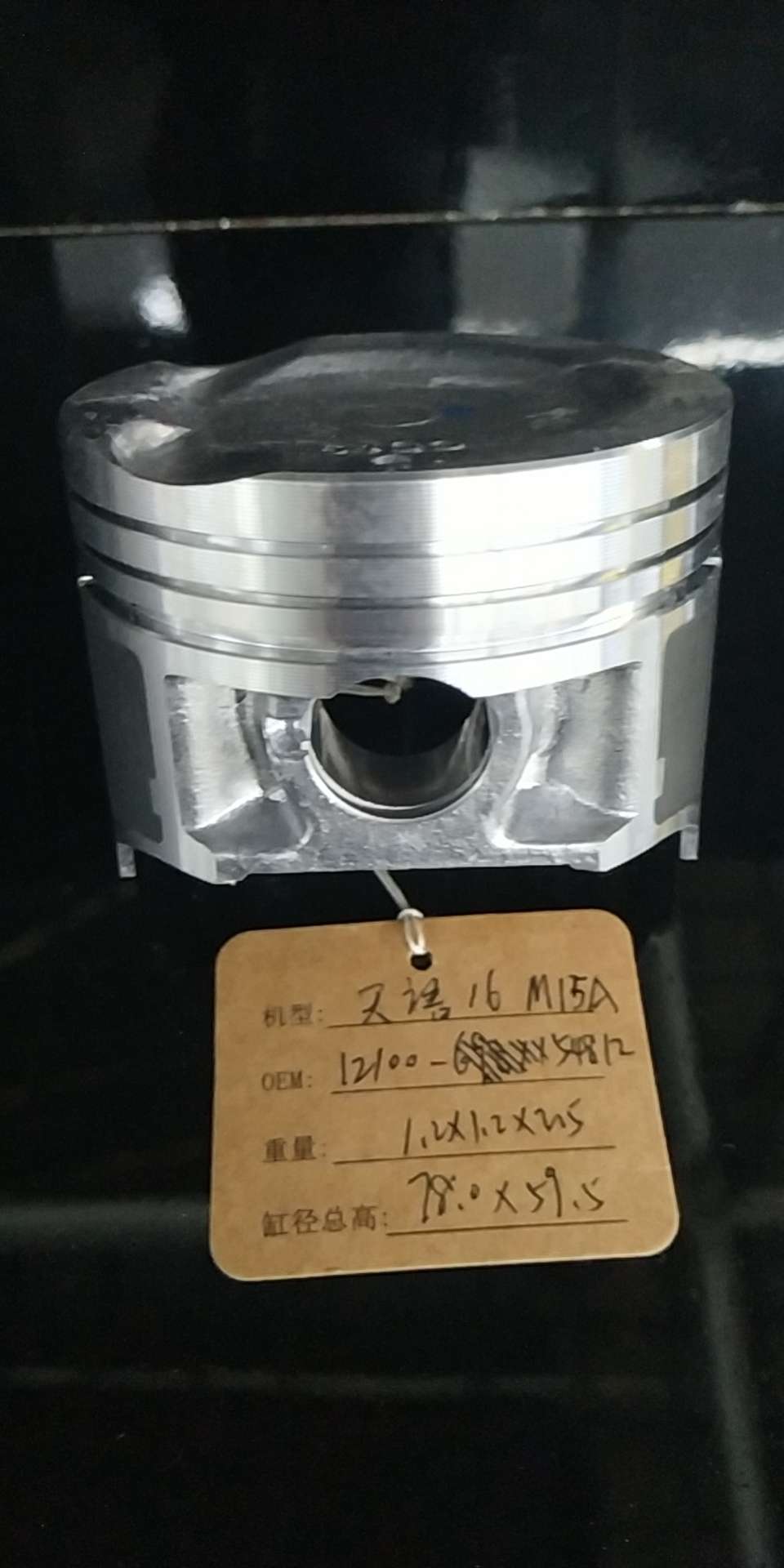

As an important part that drives the operation of the entire engine, the piston assembly is responsible for converting the energy generated by fuel combustion into mechanical motion, thereby pushing the vehicle forward. Its precise design and solid quality determine whether the power output and stability of the vehicle are excellent. For models equipped with Suzuki M13A engine, the total achievement of a set of high-quality pistons is like putting a reliable shield on this "heart.

The secret of performance upgrades: the combination of quality materials and craftsmanship

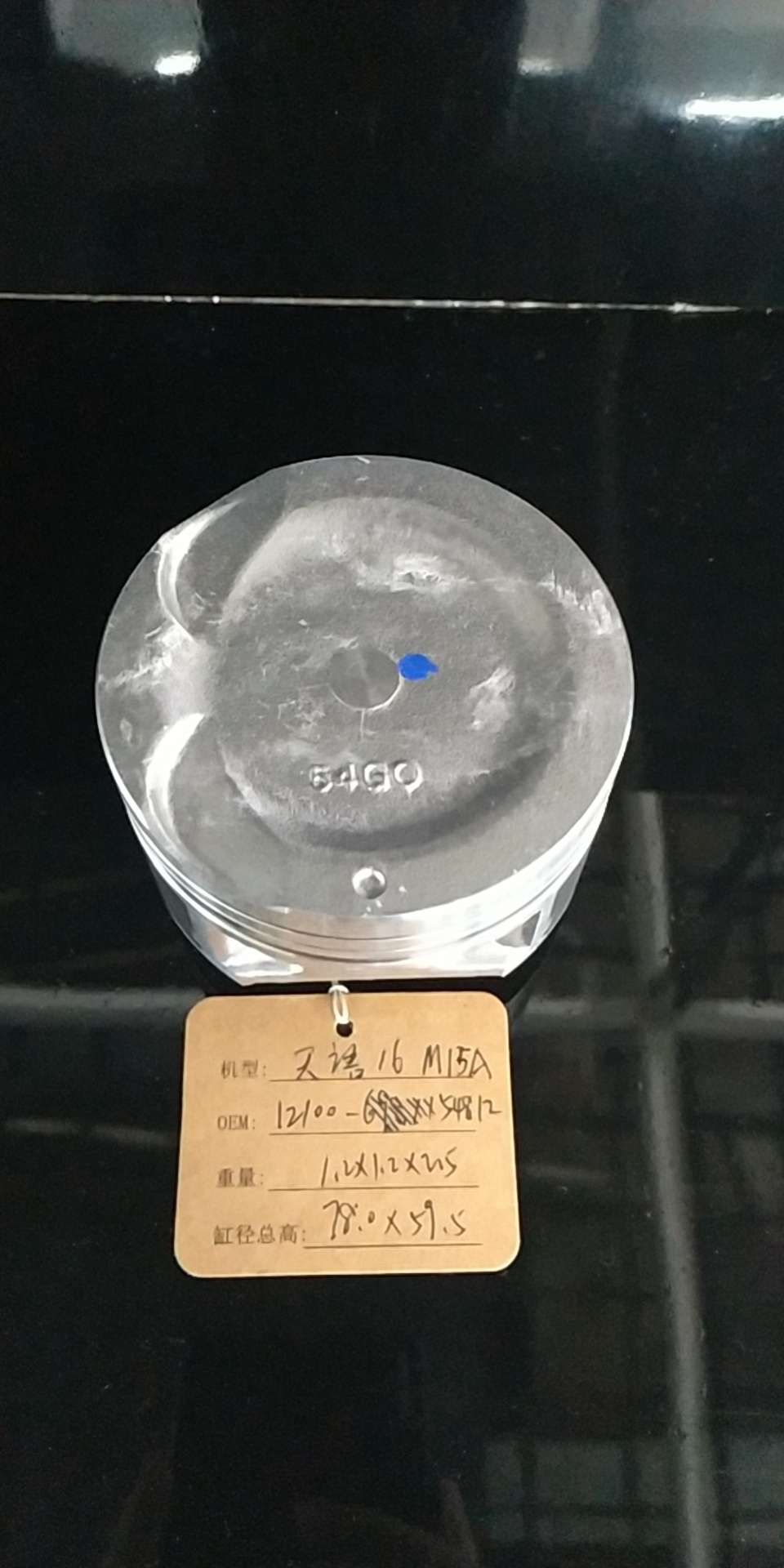

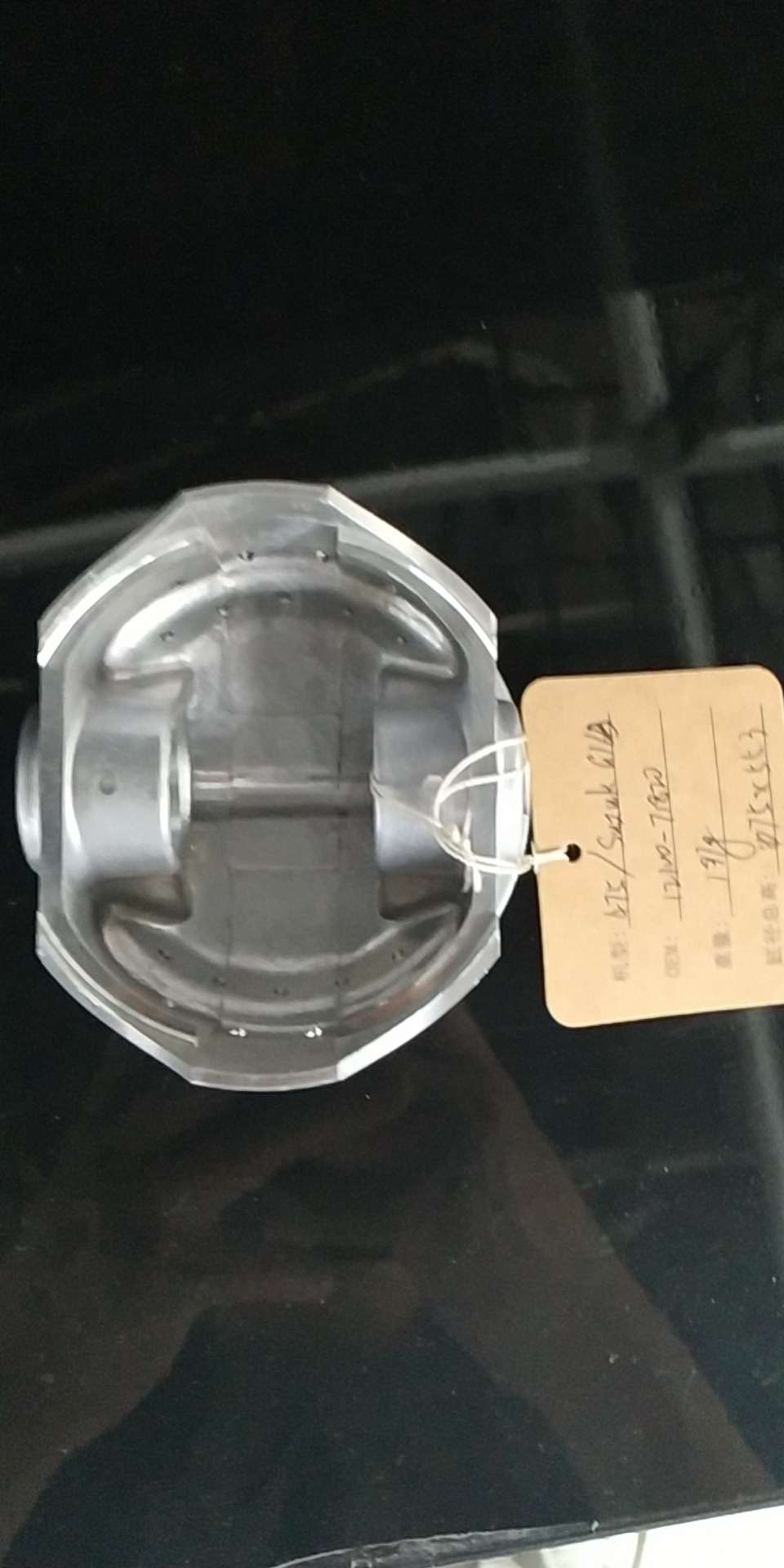

In order to ensure long-term stable and high-performance performance, this Suzuki M13A piston assembly is made of high-strength aluminum alloy, which not only reduces the overall weight but also improves the heat resistance and compression resistance. In addition, the use of advanced CNC machining technology and strict quality inspection process in the manufacturing process enables each component to meet the millimeter-level accuracy requirements, further enhancing the sealing and balance after assembly.

Durability testing: Product design that stands the test of time

In addition to the pursuit of extreme performance, reliability is also one of the indispensable factors to measure the standard of a good accessory. Through the simulation experiments under a variety of complex working conditions, it is shown that even after thousands of hours of continuous work in a high temperature and high pressure environment, this set of piston assembly produced by the technical guidance of the original Suzuki factory can still maintain the stable working efficiency of the initial state., Really achieve the user to enjoy the driving pleasure with peace of mind.

Wide range of adaptation: the best solution to meet the needs of diverse models

considering the personalized modification or maintenance and replacement needs that different users may have, this model can be widely used in various passenger car types developed based on Suzuki M13A platform (the specific adaptation list can be confirmed by professional technicians). Whether it is a family car or a small SUV, it only takes a few simple steps to successfully complete the replacement operation, so that the car is rejuvenated.

Installation Guide and Maintenance Recommendations: Tips to Extend Product Life

finally, remind all car owners and friends that they must carefully read the attached instructions before assembly and carry out relevant procedures in strict accordance with the standard steps. In addition, regular inspection of the lubricating oil level and cleaning of internal carbon deposits are also very critical! Only in this way can we ensure that our behind-the-scenes hero is always in the best service condition.