For everyone who loves driving, exploring the inner workings of the engine is always fun and challenging. Today we focus on one of the core components of the Suzuki M13A series-the high-performance piston assembly, and learn how it improves vehicle performance.

Uncover the secrets of the Suzuki M13A: Why do you need a high-performance piston assembly?

As an important part of a classic small car, the Suzuki M13A engine is known in the industry for its efficient fuel efficiency. However, with the increasing demand for vehicle power in the market, the original configuration gradually shows some limitations. In particular, it is easy to produce wear phenomenon under high load operation, which affects the overall life. At this time, the introduction of advanced high-performance piston achievements is particularly important, it can significantly improve these problems and bring unexpected benefits.

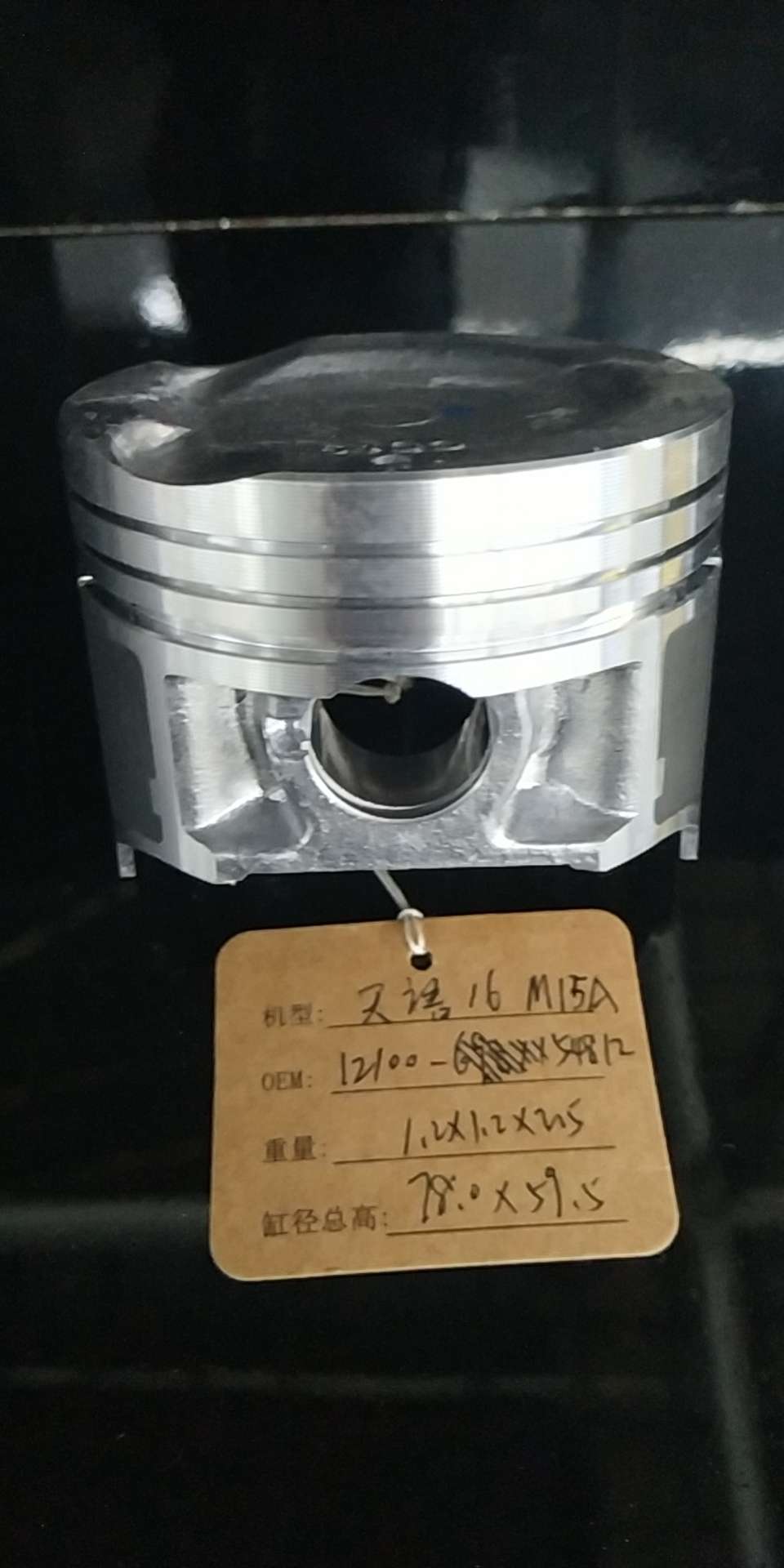

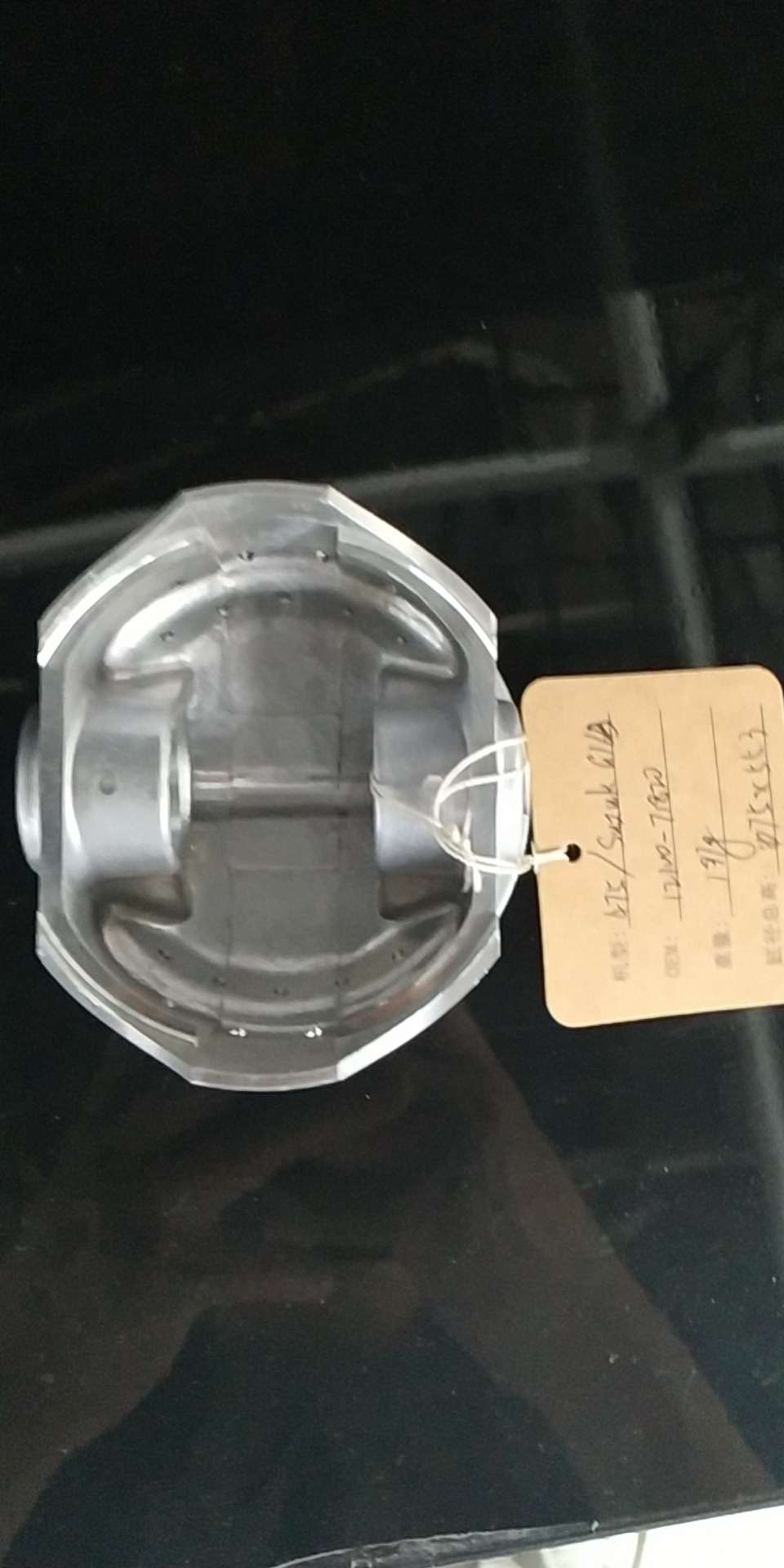

Core Technology Secret: Interpretation of Key Parameters of High Performance Piston Assembly

Let's take a closer look at what's so special about this new model! First of all, from the point of view of material selection, high-strength aluminum alloy is used for forging, which is less weight than traditional steel products but not less hardness. Secondly, special heat treatment process is used to enhance the fatigue resistance and prolong the service life. Finally, a layer of wear-resistant ceramic coating is added to cover the surface, which greatly reduces the friction coefficient and improves the work efficiency.

Momentum beyond expectations: What is the truth behind the data?

Experiments have proved that after assembling this type of parts, the maximum output power of the vehicle has increased by an average of about 15%, and the peak torque has also increased accordingly to a new height above the original value. Not only that, the acceleration response speed means that the start overtaking more confident and leisurely. Of course, in addition to the hard-core figures, we have also collected a lot of favorable feedback from car owners and friends: "Since I changed this new piece, I feel that the whole car has taken on a new look!"

The secret weapon of long-lasting reliability: How does durability define success?

In order to ensure outstanding performance in a stable operating environment for a long time, the R & D team has made detailed considerations for various complex working conditions. For example, strengthen the lubrication system and cooperate with precise clearance regulation to prevent premature drying and damage. In addition, expanding the scope of the working temperature zone to meet the needs of the four seasons will not cause trouble even if it starts in cold winter.

Fuel-efficient and environmentally friendly: energy-saving potential cannot be ignored

It is worth mentioning that this technological innovation also takes into account the mission of environmental protection responsibility. By optimizing the mixture ratio control and full combustion process, the emission of unburned substances is reduced, and the exhaust pollution index is effectively reduced in line with the current international regulatory trends. This means that consumers can enjoy both strong power and contribute to their home planet. Why not?

Hands-on Guide: Master all the steps to replace the piston correctly

if you are a friend who likes to refit your car by yourself, then this part of the content is definitely worth seeing. First of all, a full set of special tools including but not limited to basic equipment such as torque wrench socket combined with screwdriver group shall be prepared, and then the whole process of disassembly, cleaning, inspection, reassembly and restoration shall be carried out step by step according to the sequence indicated in the manual. During this period, care must be taken to avoid damage to surrounding components to avoid unnecessary losses.