Exploring the heart of the engine: Why Suzuki M13A needs a high-performance piston assembly

When it comes to automotive power systems, many people will focus on turbochargers or fuel injection systems. However, there is a crucial component behind this that is often overlooked-the piston assembly. Especially for models equipped with Suzuki M13A engine, a high quality set of piston assembly not only determines its smooth operation, but also directly affects the overall performance.

The M13A engine is known for its small size and light weight, but this also means that every component needs to meet the needs of daily driving. Especially in the high temperature and high pressure environment work piston total achievement is particularly important.

Declassify the excellent quality: analyze the core material and manufacturing process of the piston assembly

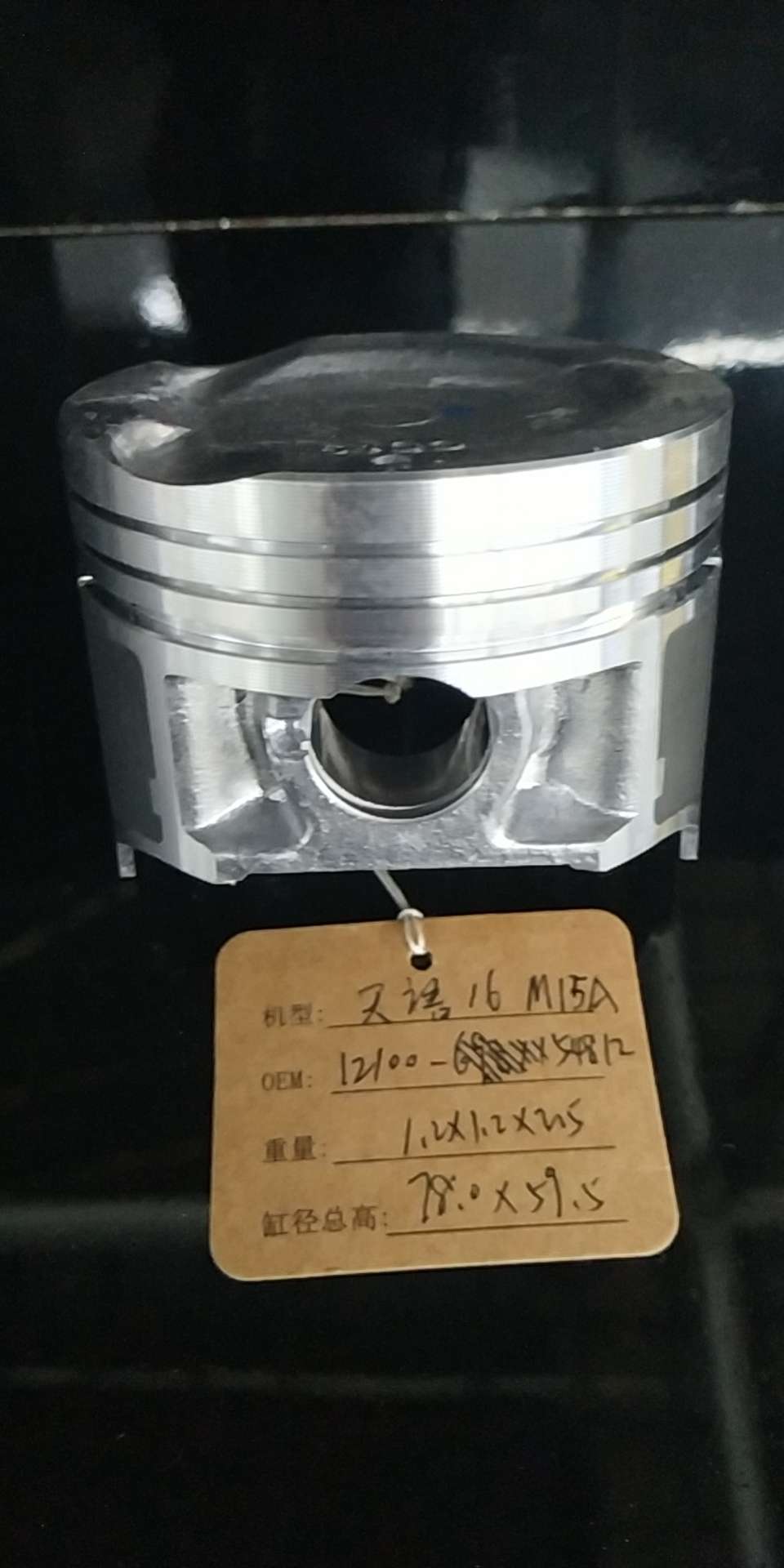

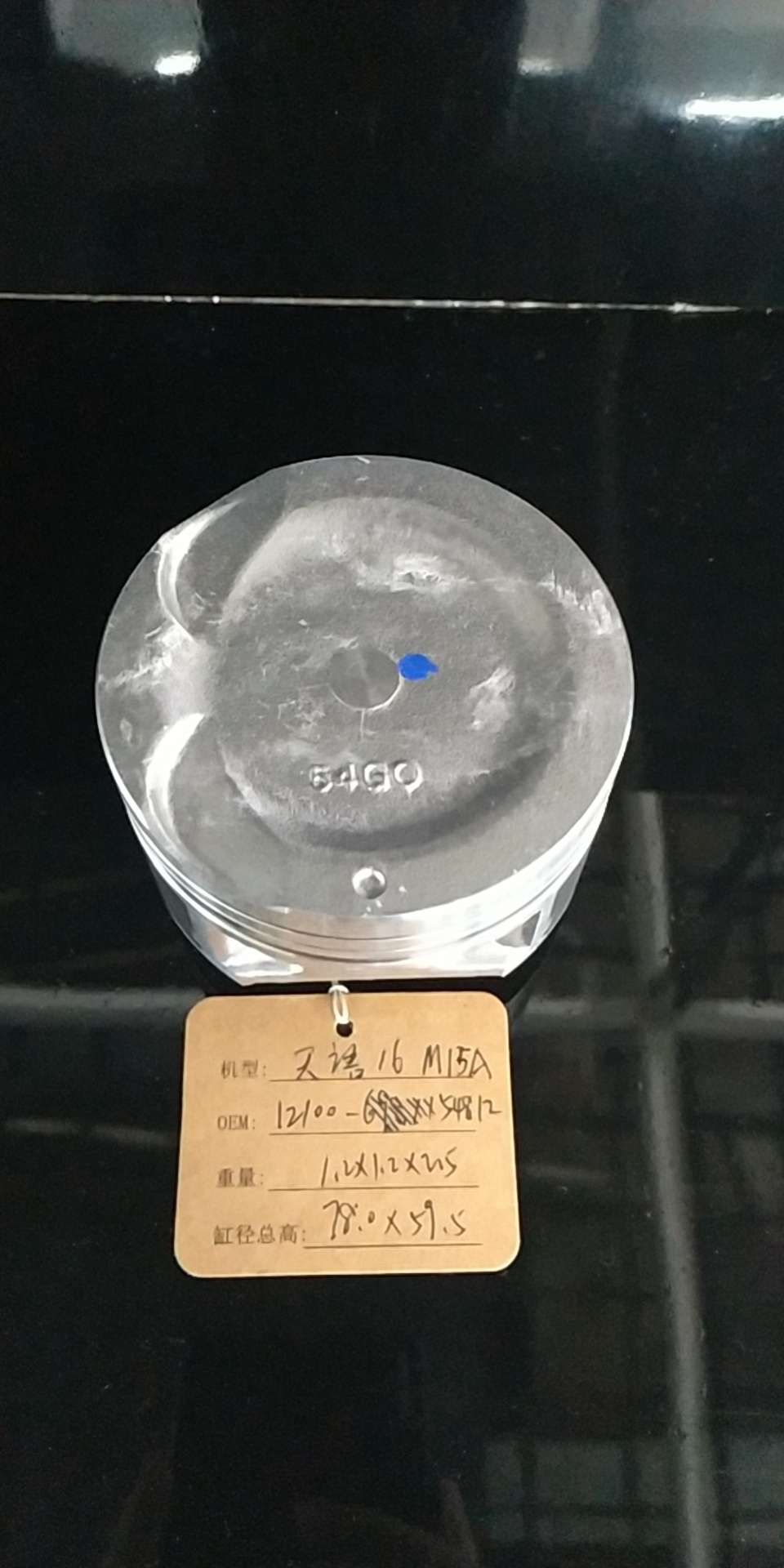

In order to achieve better durability and efficiency improvement, modern high-end pistons usually use aluminum alloy as the basic raw material, and undergo special treatment to increase strength and wear resistance. For example, the surface anodic oxidation coating can not only prevent corrosion but also reduce the coefficient of friction, making long-term operation more stable and reliable.

In addition, precision casting technology and advanced CNC machining also ensure the production of products with precise shapes and uniform weight distribution. These factors work together to make each part able to withstand extreme conditions.

The way to jump performance: how the piston assembly determines the power performance of the engine

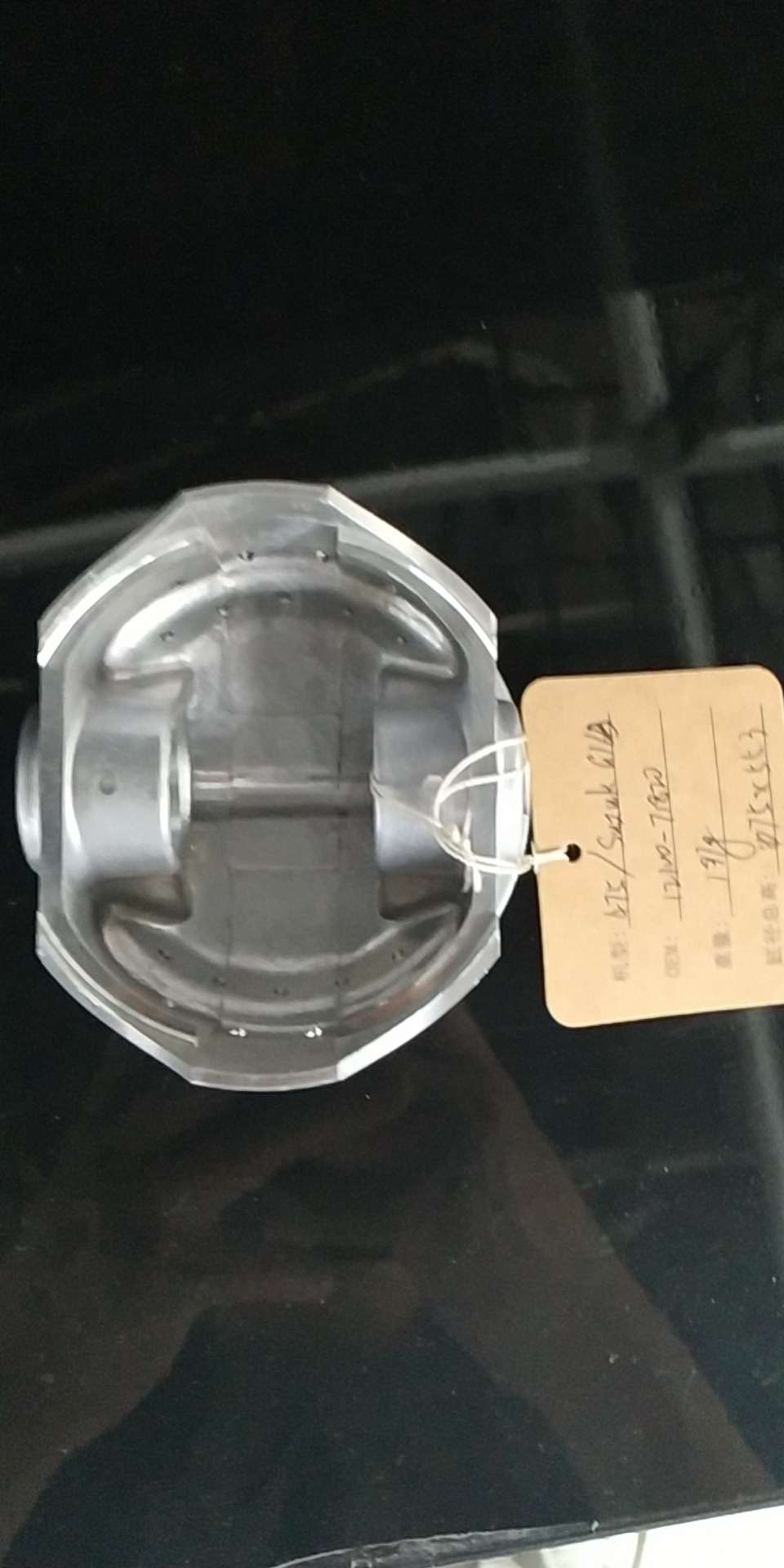

Although it appears to be a device composed of several metal blocks, in fact it plays an extremely critical role in the entire combustion cycle. Firstly, the compressed air mixture forms a sufficient pressure and then ignites to generate explosive force to push the crankshaft to rotate to complete the work steps; secondly, due to the tightly matched design scheme, unnecessary energy loss is reduced, the heat conversion ratio is improved, and the acceleration response speed of the vehicle is enhanced. And stability.

In addition, the well-balanced design also helps to eliminate vibration and prolong service life while improving ride comfort.

Practical experience sharing: How to properly maintain and replace the piston assembly for car owners

although the original assembly parts have been strictly tested and verified to pass the factory, aging and wear will inevitably occur, so regular inspection is one of the necessary preventive measures. It is recommended that professional testing be carried out every 20,000 kilometers. If abnormalities are found, they should be repaired in time to avoid greater damage.

If you plan to disassemble and install yourself, be sure to follow the procedures in the official instruction manual and have all the necessary tools at hand to ensure that the task is completed safely and accurately.

Market preferred recommend: Best piston assembly option for Suzuki M13A

Choosing the ideal accessory for your car among the many brands on the market can be confusing. Here we have specially selected several well-received choices for you:

-The first standard model from the well-known manufacturer XYZ Company has won the support of a large number of loyal customers with years of accumulated technical experience and strict quality control system;

-In addition, there is an upgraded version of the ABCD brand for those pursuing higher performance limits to consider. Its unique design concept gives more powerful data parameters and longer service cycle life.

No matter which choice is based on customer needs to create an excellent solution hope to help friends who are looking for the right product!