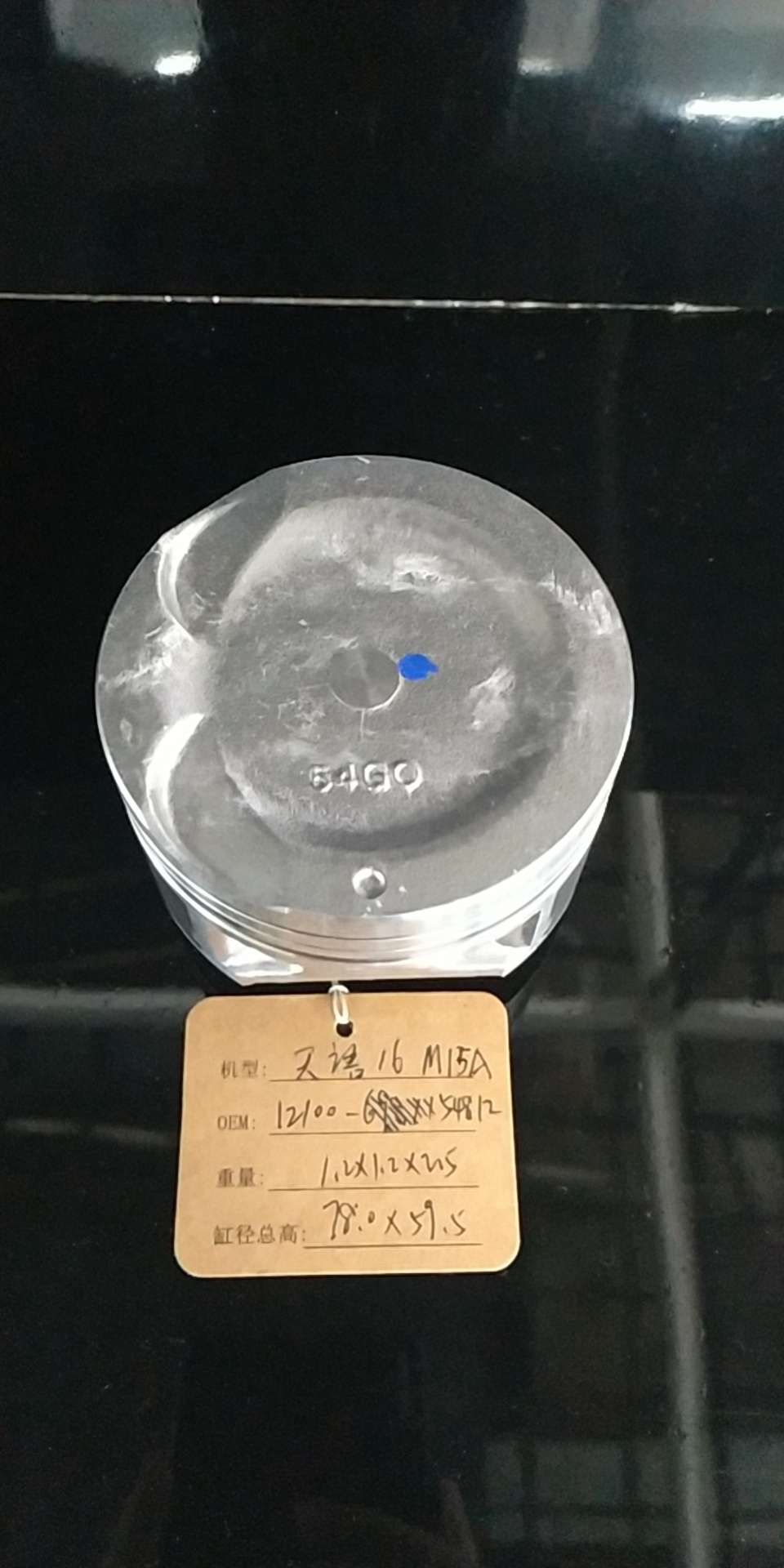

Suzuki M13A piston assembly: the core power source of excellent performance

The engine is called the heart of the car, and inside this heart, there is an indispensable key component-the piston assembly. As one of the most core components in the energy conversion process, the piston assembly directly affects the power output and overall performance of the vehicle.

Compared with ordinary parts, the Suzuki M13A series uses higher specification materials and technologies, which make it have stronger wear resistance and higher heat conduction efficiency. This unique advantage makes it stand out in the market and become an ideal alternative for many car owners.

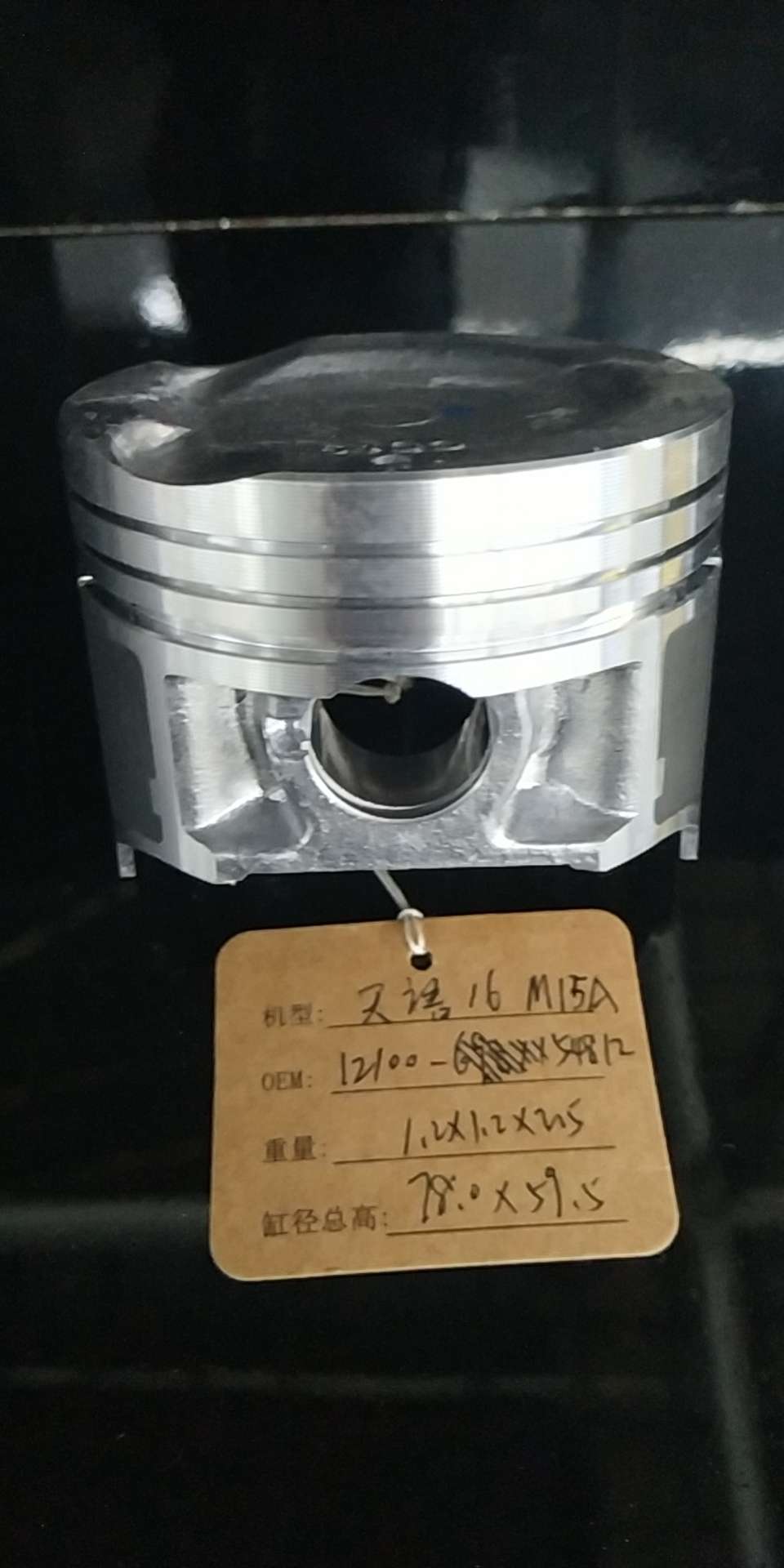

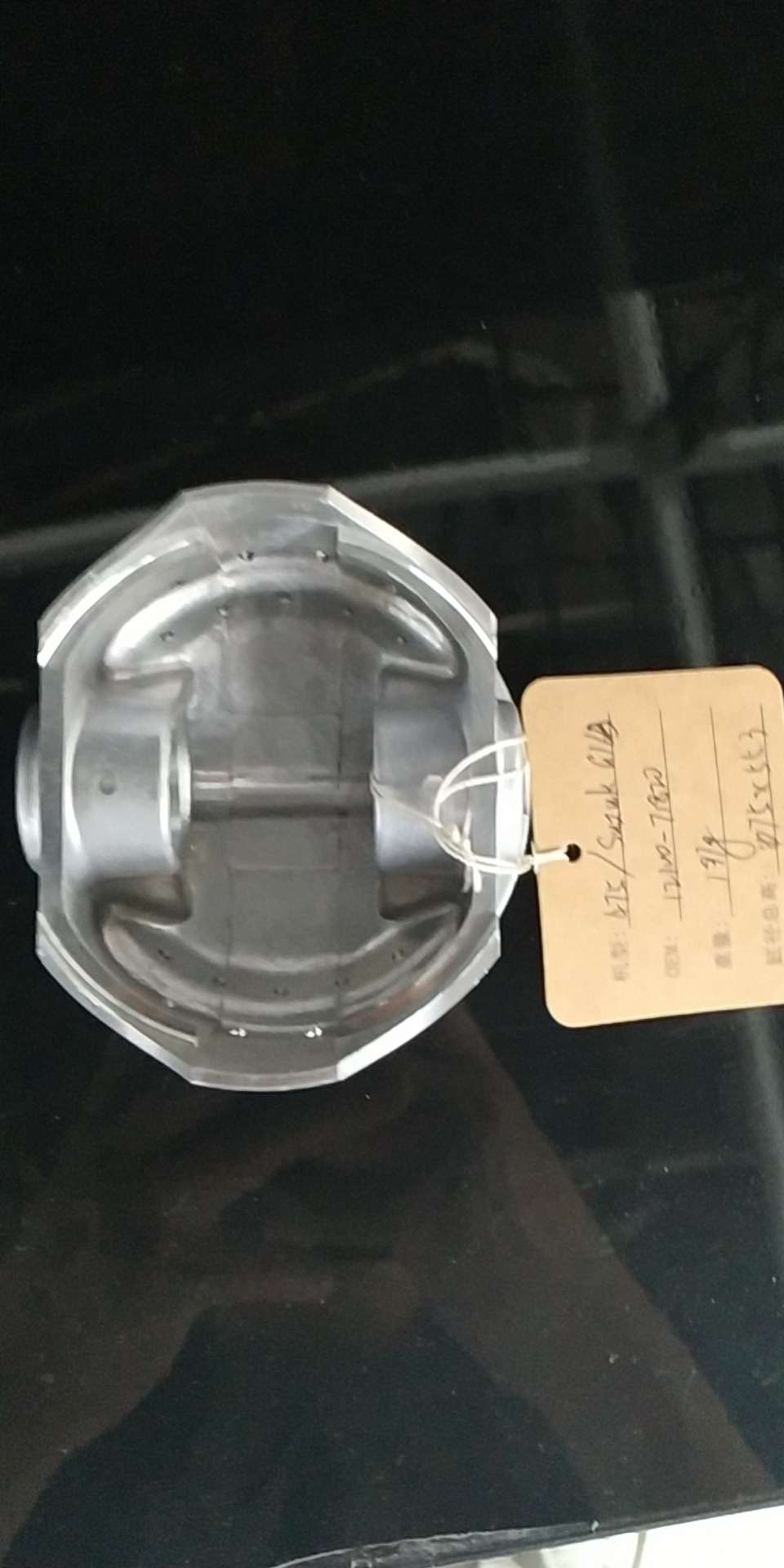

Every product produced by Suzuki embodies the spirit of craftsmen and the crystallization of cutting-edge technology. This precision device, specially customized and developed for the M13A model, strictly implements various inspection procedures under the requirements of the International Organization for Standardization ISO system in the manufacturing process. By introducing CNC machine tools for high-precision cutting operations, the surface roughness index value is greatly reduced; at the same time, the use of advanced coating treatment technology effectively reduces the mechanical resistance generated during operation to extend the service life of the entire system.

In order to achieve long-term and reliable operation, the piston is made of a variety of high-grade alloy elements mixed according to scientific proportions. These special proportions can still show excellent toughness without deformation in the face of harsh working conditions. Not only that, they also have excellent oxidation and corrosion resistance, even in a humid saline environment can be calmly dealt.

With a rigorous experimental verification process, we have accumulated a large number of valuable first-hand data to prove its excellent properties. Detailed records are available for analysis at each stage, from static conditions to dynamic simulation to actual road condition testing. The data show that after being equipped with this type of equipment, not only the horsepower has increased significantly, but also the fuel consumption per 100 kilometers has decreased to achieve a win-win situation. At the same time, the exhaust emissions are also in line with the current latest regulatory limits, and the identity of the practitioner of the green travel concept is truly fulfilled.

many loyal users have left messages saying that since the switch to the new parts, there will be no more frequent failures and repairs. "I was always worried about breaking down halfway before, but now I can run long distances with confidence and boldness," said a freight forwarder who often commutes between urban and rural areas. "In addition, the after-sales team is also very professional and patient in answering all kinds of questions, which makes me feel very secure".

If you are looking for a solution that is easy to install and safe and effective, here is a simple tutorial to help you complete the upgrade task. First of all, confirm whether the required special tools are complete. Second, gradually disassemble the old parts and insert the new parts according to the instructions of the drawings. Pay attention to keeping clean and prevent impurities from mixing. Finally, check the tightness of the connection of each part to ensure that there is no sign of looseness. You can officially start and experience a brand-new driving pleasure! Remember to do the necessary lubrication and maintenance regularly, so that the effect can be maintained for a longer time.