Uncover the secrets of the Suzuki M13A piston assembly: a list of core components

For any motorcycle, the engine is undoubtedly one of its most important parts. In the Suzuki M13A engine, the piston assembly is the soul that determines the performance of the vehicle. This complex mechanism is made up of a number of sub-assemblies including, but not limited to, pistons, piston rings, and connecting rods. Each component has its own distinct mission and must work closely together to ensure the proper functioning of the entire system.

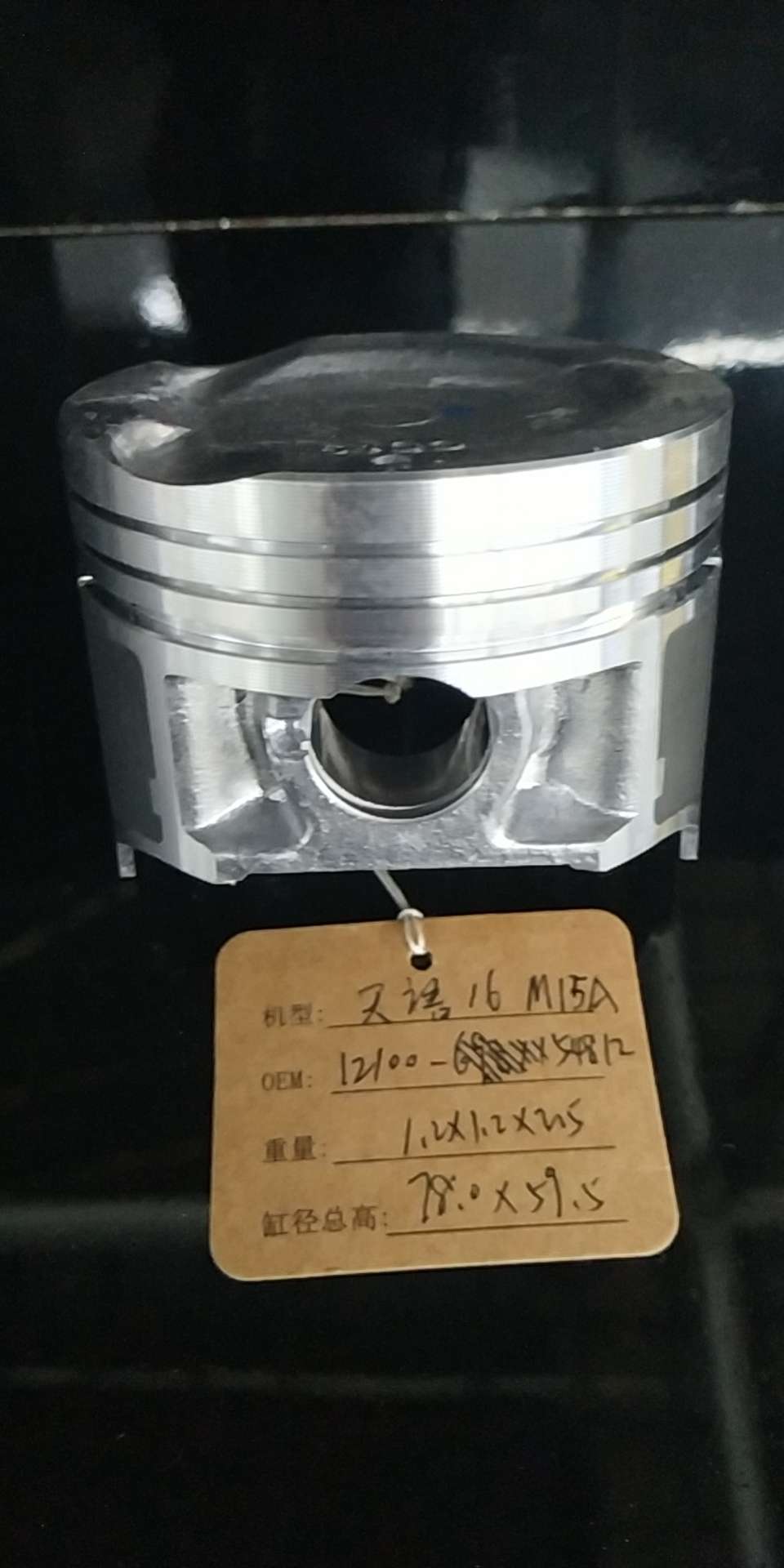

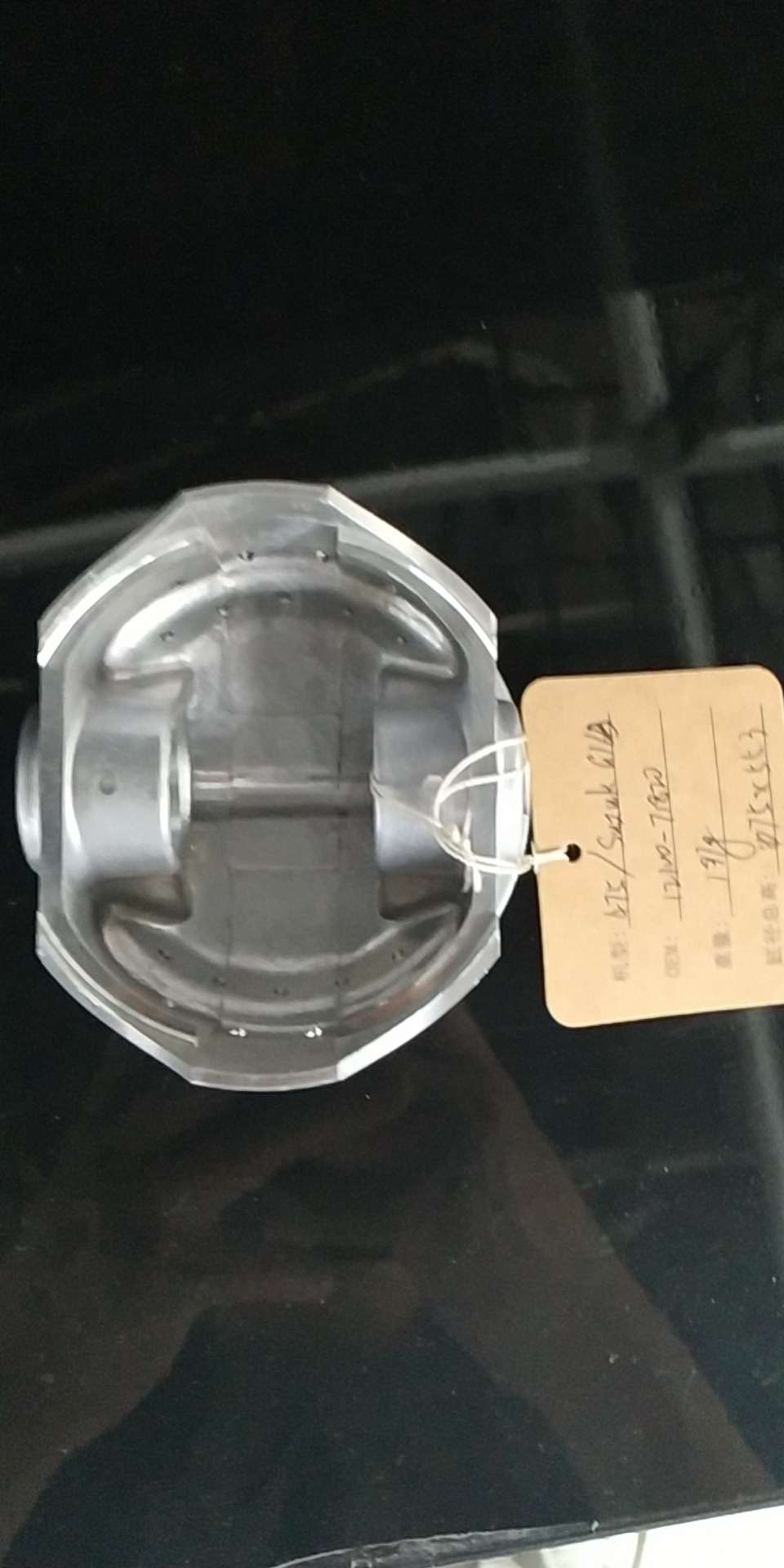

First, let's take a look at the piston as the main moving body. Its shape is usually cylindrical or oval, and it reciprocates up and down in the cylinder to push the crankshaft to rotate. In order to ensure sealing and heat dissipation efficiency, several piston rings made of thin metal are usually installed on the top. Although these small parts look inconspicuous, they play a vital role-preventing the leakage of combustion gases while also taking away excess heat.

Let's talk about the bridge between the piston and the crankshaft-the connecting rod. Due to the extreme pressure and impact, it needs to be made of high-strength steel. The precise design allows it to operate at high speeds without excessive deformation, thereby improving overall stability. In addition, there are other auxiliary components such as thrust washers, etc. also play an irreplaceable role.

Technical Decryption: Precisely Matched Materials and Manufacturing Processes

It is not easy to create a durable and efficient piston assembly, which cannot be separated from carefully selected materials and rigorous production processes. In terms of material selection, engineers will choose aluminum alloy with good wear resistance and fatigue resistance to cast the main piston. This lightweight alloy not only reduces its own weight to increase the upper speed limit, but also has excellent thermal conductivity, which helps to reduce the operating temperature.

At the same time, special steel or titanium alloy is used to strengthen those parts that require higher hardness. For example, the area near the position of the fixed pin hole will increase the surface hardness value by carburizing and quenching. For some places with frequent friction, it may be covered with a ceramic coating to further enhance the corrosion resistance and lubrication effect.

In the entire assembly process, every step needs to be strictly implemented in accordance with the standard. From the initial rough machining of the rough parts to the final fine grinding assembly and debugging, it has to go through many strict testing links. Only in this way can we ensure that every factory product can meet the expected target requirements and withstand the test of long-term use.

Data Talk: Detailed Explanation of Key Specifications and Performance Indicators

The best way to understand a product is to check its official technical parameter form. Here are some important information about the Suzuki M13A piston assembly:

- Size: The diameter is about 73mm; the length is about 90mm.

- Weight: The entire component weighs about 1kg.

- Compression ratio: has reached an astonishing level of 12:1 or more.

- Maximum power output: It can provide more than 60 horsepower power support under high load conditions.

These numbers are not just cold words, they reflect the strength of the model in the actual use environment. Especially in the acceleration response speed is particularly prominent, even in the face of complex road conditions can quickly respond and maintain a stable driving state. In addition, it is worth noting that its good fuel economy performance is also impressive, with an average fuel consumption of less than two liters per 100 kilometers, which is undoubtedly good news for the new generation of consumers pursuing the concept of energy conservation and environmental protection.

Maintenance Guide: Best Practices for Extended Service Life

In order to keep your car in the best working condition, correct maintenance is essential. Regularly checking whether the lubricating oil level is sufficient is one of the first tasks. Because if the lack of the necessary lubricant can lead to internal components dry contact with each other causing serious damage or even permanent failure. Therefore, it is recommended to open the dipstick every once in a while to observe carefully, and add an appropriate amount of new oil when necessary to maintain normal fluidity.

Secondly, it is necessary to clean up the impurity particles in the air filter in time to avoid inhaling too much dust to affect the intake air volume and cause the mixing ratio imbalance. At the same time, pay attention to cleaning the carbon deposits around the spark plug to ensure that each spark can be successfully ignited fuel full combustion release more energy. Of course, don't forget to carry out regular maintenance and replacement of aging and damaged parts according to the time period given by the manufacturer is also an essential operation step!

the last point is also very critical is to develop good driving habits, such as warming up the engine for a few minutes before starting, giving each movable joint enough time to warm up before starting. Don't turn off the engine brake system immediately after parking, and then turn off the power switch after completely cooling down. This is conducive to reducing unnecessary wear and prolonging the life of the machine.